To install a pressure switch, first, turn off the power supply. Then, disconnect the existing wires and remove the old switch.

Next, connect the wires to the new pressure switch, making sure to match the markings and colors. Finally, secure the switch in place and restore the power supply. Now, let’s delve into the details of how to install a pressure switch for your convenience.

A pressure switch is a vital component in various systems, such as water pumps, air compressors, and HVACs. It helps maintain the desired pressure levels by controlling the on/off cycles of the system. Whether you need to replace a faulty switch or install a new one, understanding the installation process is crucial. We will guide you through the step-by-step instructions to successfully install a pressure switch. So, let’s get started and ensure the efficient operation of your system.

The Importance Of Pressure Switches In Household Appliances

A pressure switch is a critical component in many household appliances, playing a key role in maintaining their optimal performance. These switches are responsible for monitoring and regulating the pressure levels within appliances, ensuring that they operate smoothly and efficiently. Without pressure switches, appliances like refrigerators, washing machines, and air conditioners would be prone to damage and malfunctions, leading to costly repairs or replacements.

Role of pressure switches in maintaining optimal performance

Pressure switches are designed to monitor and control the pressure levels within household appliances. They act as a safety mechanism, ensuring that the appliances operate within their specified pressure range. By maintaining optimal pressure levels, these switches help to prolong the lifespan of appliances and enhance their overall performance.

Here are some ways in which pressure switches contribute to maintaining optimal performance:

- Regulating the pressure: Pressure switches are responsible for accurately monitoring the pressure levels within appliances. They are programmed to detect any deviations from the desired pressure range and take appropriate action. This could involve activating or deactivating certain components to restore the pressure to the optimal level.

- Preventing overpressure: Overpressure can cause severe damage to household appliances, leading to leaks, breakages, or even explosions in extreme cases. Pressure switches are designed to prevent overpressure situations by shutting down the appliance when the pressure exceeds the safe limit. This ensures the safety of both the appliance and the users.

- Ensuring consistent performance: Pressure switches help in maintaining consistent performance of appliances by regulating the pressure levels. This ensures that appliances function as intended, delivering the desired results consistently without any fluctuations or variations in performance.

How pressure switches prevent potential damage and malfunctions

Pressure switches play a crucial role in preventing potential damage and malfunctions in household appliances. Their proactive monitoring and control capabilities help in avoiding costly repairs or replacements. Here’s how pressure switches prevent potential damage:

- Early detection of issues: Pressure switches are equipped with sensors that can detect abnormalities or pressure deviations within appliances at an early stage. This allows for prompt intervention and prevents further damage by addressing the issues before they escalate.

- Immediate action: When pressure switches detect a problem with the pressure levels, they can take immediate action to rectify the issue. This may involve shutting down the appliance or activating specific components to restore the optimal pressure. By acting swiftly, pressure switches help prevent potential damage caused by prolonged exposure to abnormal pressure levels.

- Protection against excessive wear and tear: When appliances operate under abnormal pressure conditions for prolonged periods, it can lead to excessive wear and tear of components. Pressure switches prevent such situations by ensuring that appliances operate within the specified pressure range. This helps in preserving the longevity of appliances and reducing the need for frequent repairs or replacements.

Overall, pressure switches serve as a safeguard for household appliances, ensuring their smooth operation and preventing potential damage. By constantly monitoring the pressure levels and taking necessary actions, these switches play a vital role in enhancing the performance and longevity of appliances, saving both time and money in the long run.

Understanding Pressure Switches And Their Components

A pressure switch is an important component used in various applications to monitor and control the pressure of fluids or gases. It plays a critical role in regulating the operation of a system, ensuring optimum performance and safety. To fully grasp how pressure switches work, it is essential to have a comprehensive understanding of their components.

Definition and Function of Pressure Switches

A pressure switch, as the name suggests, is a device that detects changes in pressure and reacts accordingly. It consists of several components that work together to monitor the pressure levels and trigger specific actions based on predetermined setpoints. The primary function of a pressure switch is to open or close an electrical circuit based on the pressure conditions.

Overview of the Different Components within a Pressure Switch

Pressure switches are made up of several key components, each serving a specific purpose. Familiarizing yourself with these components will enable you to understand the inner workings of a pressure switch. Let’s take a closer look at them:

1. Sensor: The sensor is a vital component of a pressure switch. It is responsible for sensing the changes in pressure and converting them into electrical signals. The type of sensor used can vary depending on the application, with common options including diaphragms, bellows, or Bourdon tubes.

2. Setpoint Adjustment: The setpoint adjustment allows you to define the desired pressure level at which you want the pressure switch to activate. It is typically a dial or knob that can be adjusted to specific pressure units (psi, bar, kPa) and serves as a reference point for the switch’s operation.

3. Contacts: The contacts within a pressure switch are responsible for opening or closing the electrical circuit based on the pressure conditions. When the pressure reaches the setpoint, the contacts will either make or break the circuit, initiating a specific action such as activating a pump or turning off a compressor.

4. Housing: The housing is the protective casing that encloses all the internal components of the pressure switch. It ensures that the switch remains intact and safe from external factors such as dust, moisture, or mechanical damage.

5. Electrical Connections: Pressure switches feature electrical connections that allow them to be integrated into a larger electrical system. These connections are usually in the form of terminals or wires that can be easily connected to other electrical components.

6. Adjustment Mechanism: In some pressure switches, an adjustment mechanism is provided to fine-tune the switch’s sensitivity. This mechanism allows you to modify the response of the switch according to the specific requirements of the application.

By understanding the various components of a pressure switch, you can effectively install and troubleshoot any issues that may arise. Whether you’re dealing with fluid or gas pressure, having a solid grasp of pressure switch components will help you ensure optimal performance and maintain the overall efficiency of your system.

Step-By-Step Guide To Installing A Pressure Switch

In this step-by-step guide, we will walk you through the process of installing a pressure switch. Whether you’re a seasoned DIY enthusiast or a beginner in the world of appliance repairs, you’ll find this guide helpful in successfully installing a pressure switch. We’ll cover everything from gathering the necessary tools and materials to testing the functionality of the pressure switch.

Gathering the necessary tools and materials

Before you begin the installation process, it’s essential to have the right tools and materials at hand. Here’s a list of items you’ll need:

- Pressure switch

- Screwdriver

- Wire strippers

- Electrical tape

- Multimeter

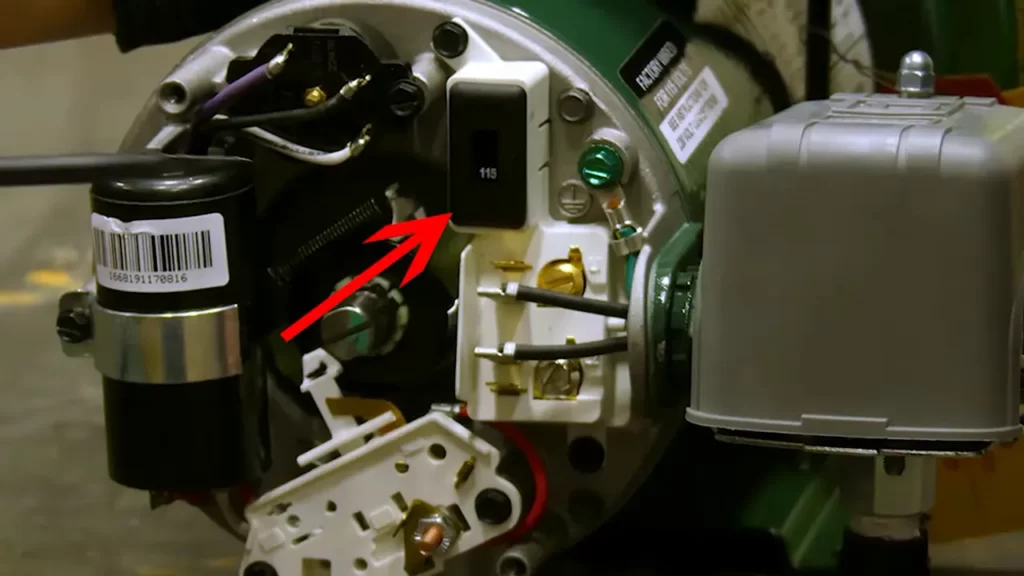

Locating the pressure switch within the appliance

Next, you need to locate the pressure switch within your appliance. Consult the appliance’s user manual or schematic diagram to find the exact location. In most cases, the pressure switch is located near the control panel or inside the appliance’s housing.

Disconnecting the power supply before installation

Prior to installing the pressure switch, it’s crucial to disconnect the power supply to eliminate the risk of electric shock. Locate the main power switch or unplug the appliance from the electrical outlet.

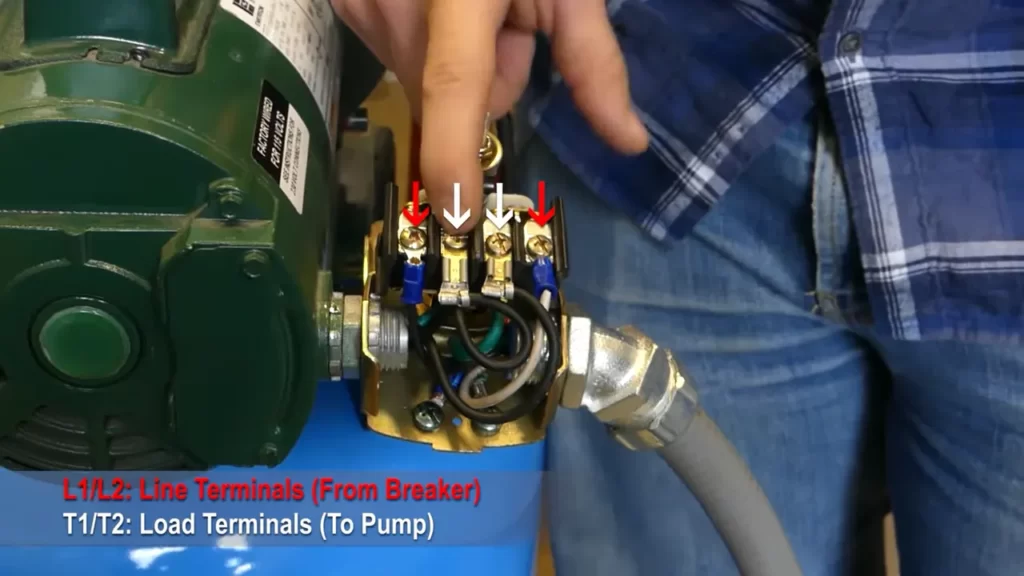

Understanding the wiring diagram and connections

Every pressure switch comes with a wiring diagram that shows how the connections should be made. Take a moment to study the diagram and understand the different terminals and their functions. This will ensure a smooth installation process and prevent any potential wiring errors.

Installing the pressure switch correctly

Now, let’s move on to the installation of the pressure switch. Follow these steps:

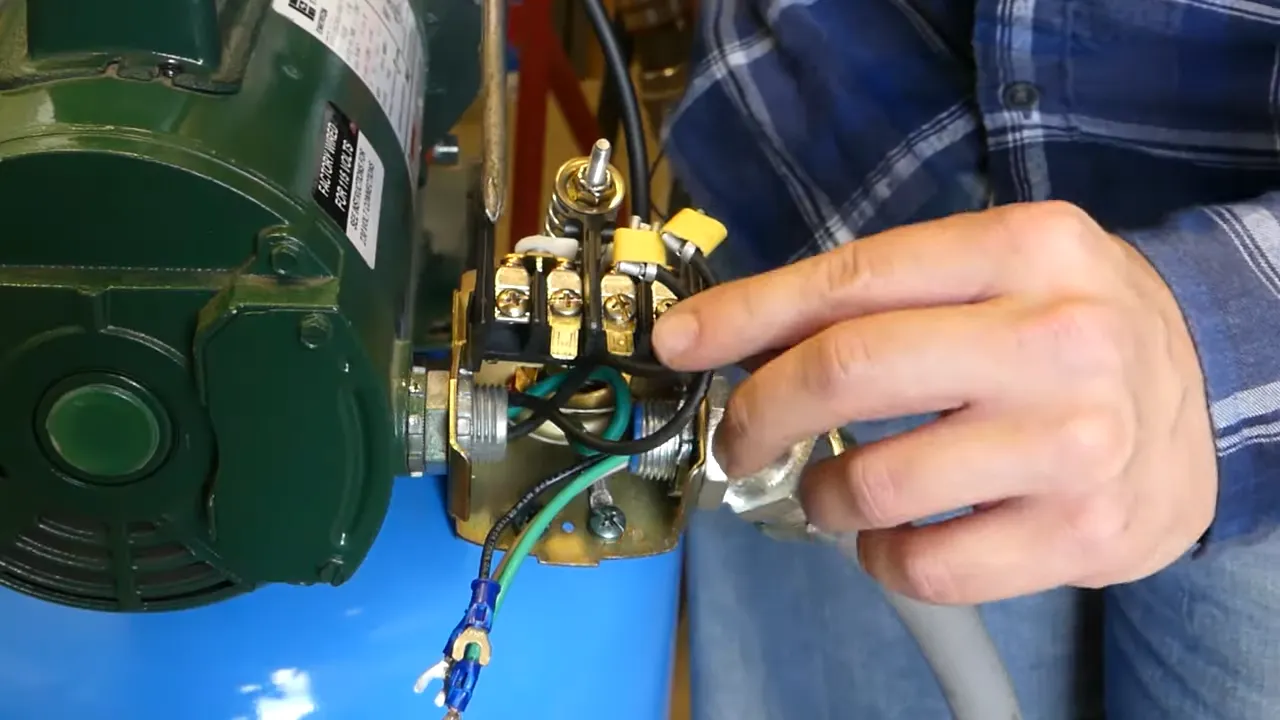

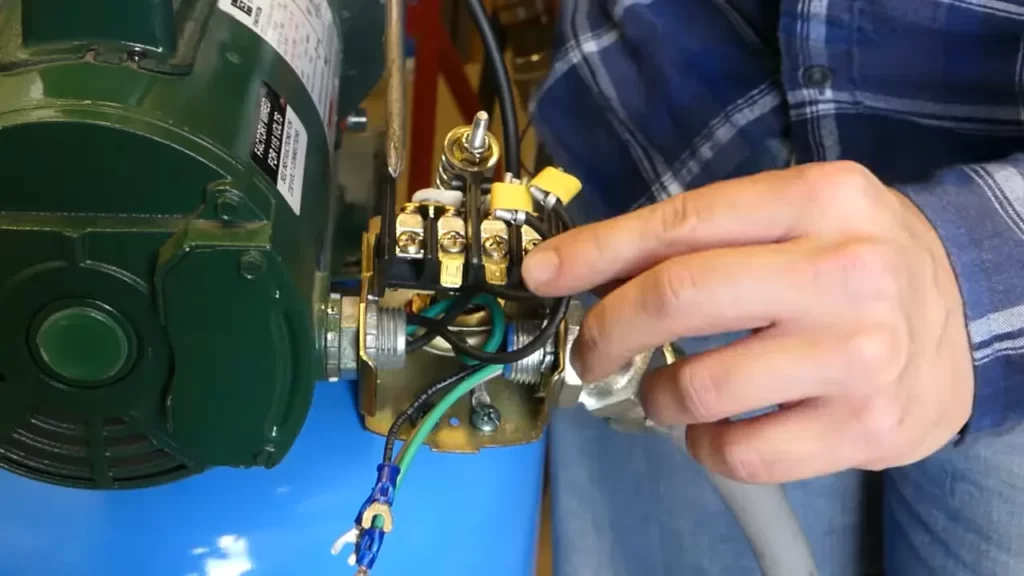

- With the power disconnected, remove the wires from the existing pressure switch by loosening the terminal screws.

- Take the new pressure switch and connect the wires according to the wiring diagram. Make sure to match the wire colors and firmly tighten the terminal screws.

- Double-check all connections to ensure they are secure and properly aligned.

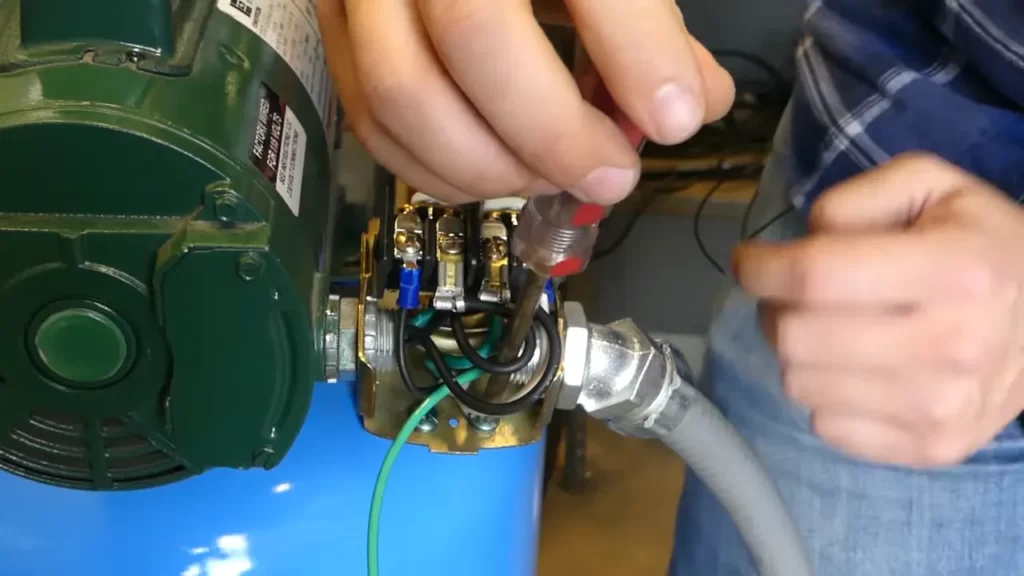

Testing the pressure switch for functionality

Once the pressure switch is installed, it’s time to test its functionality. Use a multimeter to check if it is working correctly. Set the multimeter to the appropriate voltage range and carefully measure the voltage across the terminals of the switch. The reading should match the specifications provided in the user manual. If the reading is within the expected range, then the pressure switch is functioning as intended.

By following this step-by-step guide, you can confidently install a pressure switch in your appliance. Remember to always prioritize safety by disconnecting the power supply before starting any installation process. Good luck!

Troubleshooting Common Issues With Pressure Switches

Identifying signs of a malfunctioning pressure switch

If you notice any abnormal behavior with your pressure system, it could be an indication that your pressure switch is malfunctioning. Here are a few signs to look out for:

- Fluctuating pressure: If your pressure switch is not maintaining a consistent pressure, it may be a sign that something is wrong.

- Constant cycling: Your pressure system should cycle on and off as needed. However, if you observe frequent and rapid cycling, it could be due to a faulty pressure switch.

- No pressure at all: If your pressure system fails to build up pressure even though it is running, it is likely that your pressure switch is not working correctly.

- Excessive pressure: On the other hand, if your pressure system consistently exceeds the desired pressure, it could be a result of a malfunctioning pressure switch.

- Unresponsive system: If your pressure system does not turn on or off when it is supposed to, it could indicate a problem with the pressure switch.

- Strange noises: Any unusual or grinding noises coming from your pressure system could be a sign of a damaged pressure switch.

Possible reasons for pressure switch failure

Pressure switches can fail for various reasons. Here are a few common culprits:

- Electrical issues: Faulty wiring, loose connections, or power supply problems can lead to pressure switch failure.

- Internal damage: Over time, the internal components of the pressure switch may wear out or become damaged, rendering it ineffective.

- Contamination: Dirt, debris, or sediment can accumulate in the pressure switch, obstructing its proper functioning.

- Mechanical wear and tear: Continuous use, vibration, and environmental factors can contribute to the wear and tear of the pressure switch, causing it to fail.

- Improper installation: Incorrect installation, such as incorrect wiring or improper adjustment of the pressure switch settings, can lead to its failure.

Steps to troubleshoot and fix common pressure switch issues

When faced with pressure switch problems, follow these steps to diagnose and resolve the issue:

- Check power supply: Ensure that the power supply to the pressure switch is functioning correctly by testing the electrical connections and circuit breakers.

- Inspect the pressure tank: Examine the pressure tank for any signs of damage, leaks, or excessive corrosion. Address any issues found.

- Clean the pressure switch: If there is visible dirt or debris on the pressure switch, gently clean it using a soft brush or compressed air.

- Verify pressure switch settings: Check the pressure switch settings and adjust them if necessary, ensuring they are aligned with the desired pressure levels.

- Replace faulty components: If all else fails, consider replacing any faulty or worn-out components, such as the pressure switch itself or the sensing mechanism.

- Consult a professional: If you are unable to diagnose or fix the pressure switch issue on your own, it is best to seek assistance from a professional technician.

By following these troubleshooting steps, you can effectively identify and address common pressure switch issues, ensuring your pressure system operates smoothly and efficiently.

Safety Precautions When Dealing With Pressure Switches

When it comes to installing pressure switches, it is crucial to prioritize safety. Pressure switch installations involve working with sensitive electrical components and potentially hazardous pressure systems. Therefore, taking proper safety precautions is of utmost importance to prevent accidents, injuries, and damage to equipment. In this section, we will discuss the importance of proper safety measures during installation and handling, as well as the potential risks and hazards associated with pressure switch installation.

Importance of proper safety measures during installation and handling

Installing a pressure switch requires careful attention to safety guidelines to ensure a smooth and accident-free process. Here are some reasons why proper safety measures are vital:

- Preventing electrical accidents: Pressure switches involve electrical connections that can pose a risk if mishandled. Following safety precautions such as disconnecting the power supply, wearing protective gear, and using insulated tools can help prevent electrical accidents.

- Ensuring personal safety: Working with pressure switch installations can expose you to potential hazards such as high pressure, sharp edges, moving parts, and hazardous materials. Implementing safety practices like wearing gloves, safety goggles, and working in a well-ventilated area is essential to protect yourself.

- Maintaining equipment integrity: By adhering to safety measures, you minimize the risk of damage to the pressure switch and associated equipment during installation. This ensures the proper functioning and longevity of the pressure switch system.

- Promoting overall workplace safety: Following safety precautions in pressure switch installation not only protects you but also contributes to a safer working environment for others. It sets a good example for colleagues and establishes a culture of safety in the workplace.

Potential risks and hazards associated with pressure switch installation

It’s essential to be aware of the potential risks and hazards involved in pressure switch installation. Understanding these risks will enable you to take necessary precautions to minimize accidents. Here are some common risks associated with pressure switch installation:

- Electrical shock: Touching live electrical parts of the pressure switch without proper precautions can result in electric shock. Remember to cut off the power source before starting any work involving electrical connections.

- High-pressure hazards: Depending on the application, pressure switches may be connected to systems with high pressure. Mishandling such systems can lead to burst pipes, leaking connections, or other dangerous situations. Follow appropriate guidelines and release pressure from the system before any maintenance or installation work.

- Chemical exposure: Some pressure switches are used in environments where they may come into contact with hazardous chemicals. Familiarize yourself with the chemicals involved and ensure proper ventilation, the use of protective gear, and compliance with safety regulations when working with these switches.

- Sharp edges and moving parts: During the installation process, ensure that you are aware of any sharp edges or moving parts associated with the pressure switch. Use caution and appropriate tools to avoid cuts, pinching, or entanglement.

By understanding the importance of safety measures and being aware of potential risks, you can significantly reduce the likelihood of accidents and ensure a smooth and secure pressure switch installation process. Prioritizing safety not only protects you but also contributes to the overall well-being of your workplace.

Expert Tips For Maintaining And Extending The Lifespan Of Pressure Switches

Pressure switches are essential components in various applications, ensuring the efficient operation and protection of systems and equipment. To maximize their performance and lifespan, it is crucial to follow expert tips for maintaining and extending the lifespan of pressure switches. By regularly inspecting and cleaning pressure switches, avoiding common mistakes that can damage them, and implementing best practices for preventing failure, you can ensure their optimal functionality and avoid costly repairs or replacements.

Regular Inspection and Cleaning of Pressure Switches

Regular inspection and cleaning play a significant role in ensuring the longevity of pressure switches. Over time, dust, dirt, and debris can accumulate on the switch, negatively impacting its performance. To prevent this, here are a few expert tips:

- Perform visual inspections: Regularly examine the pressure switch for any signs of damage or wear. Look out for loose connections, frayed wires, or corroded terminals. Address any issues promptly to prevent further damage.

- Clean the switch: Use a soft, lint-free cloth to wipe away any dust or debris on the surface of the pressure switch. Be careful not to use harsh chemicals or excessive moisture that may damage the switch.

- Check for proper alignment: Ensure that the pressure switch is properly aligned and securely fixed in its mounting location. Any misalignment can affect its functionality and lifespan.

- Inspect pressure connections: Make sure the pressure connections are clean and free from any obstructions. Clogged or blocked connections can disrupt the switch’s operation.

Avoiding Common Mistakes that can Damage Pressure Switches

Mistakes during installation or usage can lead to premature damage of pressure switches. To avoid these pitfalls, here are some crucial expert tips:

- Do not exceed the pressure limits: Stay within the specified pressure limits for your pressure switch. Exceeding these limits can cause the switch to malfunction or even fail.

- Avoid over-tightening connections: While it’s essential to have secure connections, over-tightening can damage the pressure switch, its fittings, or the accompanying pipework. Follow the manufacturer’s guidelines for proper tightening.

- Prevent exposure to extreme temperatures: Pressure switches may have temperature limitations, so it’s important to avoid exposing them to extremely high or low temperatures that are beyond their recommended range.

- Ensure proper electrical grounding: Accurate grounding is crucial for pressure switches to function effectively. Improper or lack of grounding can lead to electrical malfunctions and damage the switch.

Best Practices for Preventing Pressure Switch Failure

To prevent pressure switch failure and extend its lifespan, follow these expert best practices:

- Follow manufacturer guidelines: Always adhere to the manufacturer’s instructions for installation, operation, and maintenance. Paying attention to specific recommendations can significantly increase the switch’s reliability.

- Maintain consistent pressure: Avoid sudden pressure fluctuations that can strain the pressure switch. Implement pressure regulation mechanisms, such as pressure relief valves or accumulator tanks, to reduce stress on the switch.

- Protect from external elements: Shield pressure switches from direct exposure to extreme weather conditions, moisture, or corrosive substances. This can be achieved by using protective enclosures or appropriate shielding materials.

- Regularly test functionality: Periodically test the pressure switch’s functionality to ensure it responds accurately to changing pressure conditions. This will help identify any issues early on and take necessary actions to prevent failure.

By implementing these expert tips for maintaining and extending the lifespan of pressure switches, you can ensure their reliable performance and longevity. Regularly inspecting and cleaning pressure switches, avoiding common mistakes, and following best practices will help you avoid costly repairs and unnecessary system downtime.

Frequently Asked Questions

How Do You Set Up A Pressure Switch?

To set up a pressure switch, follow these steps: 1. Turn off the power supply to the pressure system. 2. Connect the switch to the power source and the device it controls. 3. Adjust the pressure switch’s settings according to the desired pressure range.

4. Secure all connections and ensure proper grounding. 5. Turn on the power supply and test the switch by activating the device.

Where Should A Water Pressure Switch Be Installed?

A water pressure switch should be installed near the water pump on the mainline entering the building.

Do I Have A 30 50 Or 40 60 Pressure Switch?

You may have either a 30-50 or a 40-60 pressure switch.

How Do You Replace A Pressure Switch On A Well Pump?

To replace a pressure switch on a well pump, turn off the power, drain the system, disconnect the wires, unscrew the old switch, screw in the new switch, reconnect the wires, and restore the power.

Conclusion

To sum up, installing a pressure switch is a simple process that can greatly improve the functionality of your system. By following the step-by-step guide provided in this blog post, you can ensure a successful installation without any complications. Remember to always prioritize safety and refer to the manufacturer’s instructions if needed.

With the pressure switch in place, you’ll have better control over your system’s performance and efficiency. Happy installing!