To install an electric fuel pump, first, locate the fuel tank and disconnect the negative battery cable. Then, remove any surrounding components to access the fuel pump.

Proceed by disconnecting the fuel lines and electrical connections from the old pump. Finally, install the new pump by reversing the removal steps, making sure all connections are secure and tight.

Choosing The Right Electric Fuel Pump

Choosing the Right Electric Fuel Pump

When it comes to installing an electric fuel pump, one of the most critical steps is choosing the right one for your vehicle. The electric fuel pump is responsible for delivering the necessary fuel to the engine, ensuring optimal performance and efficiency. Selecting the wrong electric fuel pump can lead to a variety of issues, including poor fuel delivery, engine misfires, and reduced fuel economy. In this section, we will explore the factors to consider when selecting an electric fuel pump, the importance of matching the fuel pump to your vehicle’s specifications, and how to research and compare different electric fuel pump options.

Factors to consider when selecting an electric fuel pump

There are several factors you need to keep in mind when choosing an electric fuel pump for your vehicle:

- Flow rate: The flow rate of a fuel pump is measured in gallons per hour (GPH) and refers to the volume of fuel the pump can deliver. To determine the appropriate flow rate, you need to consider your vehicle’s engine size and horsepower.

- Pressure: The fuel pressure, typically measured in pounds per square inch (PSI), is another critical factor. Different vehicles require different fuel pressures to operate optimally, so it is crucial to consult your vehicle’s manual or manufacturer for the correct fuel pressure specifications.

- Compatibility: It is essential to ensure that the electric fuel pump you choose is compatible with your vehicle’s fuel system. Check whether the pump is designed for a carbureted or fuel-injected engine, as well as the voltage requirements.

- Reliability: Look for reputable brands known for reliability and durability. Reading customer reviews and researching the reputation of the manufacturer can help you gauge the pump’s reliability.

Importance of matching the fuel pump to your vehicle’s specifications

Matching the fuel pump to your vehicle’s specifications is of utmost importance for its proper functioning and longevity. A fuel pump that does not match your vehicle’s requirements can lead to several problems:

- Poor fuel delivery, which can result in engine hesitation, stalling, or even complete engine failure.

- Inefficient fuel consumption, leading to reduced fuel economy and increased fuel costs over time.

- Overworking the fuel pump, potentially causing premature wear and failure.

- Damage to other fuel system components, such as the fuel injectors or fuel lines, due to improper pressure or flow rate.

Therefore, taking the time to understand your vehicle’s specifications and choosing a fuel pump that meets those requirements will help ensure optimal performance, efficiency, and longevity.

Researching and comparing different electric fuel pump options

Now that you are aware of the crucial factors to consider and the importance of matching the fuel pump to your vehicle’s specifications, it’s time to research and compare different electric fuel pump options. Here’s a step-by-step approach to help you make an informed decision:

- Consult your vehicle’s manual: Your vehicle’s manual will provide valuable information regarding the specifications and requirements for the electric fuel pump.

- Online research: Take advantage of online resources to explore different fuel pump options. Check manufacturer websites, online forums, and automotive blogs for reviews and recommendations.

- Compare specifications: Make a list of the potential fuel pumps that meet your vehicle’s requirements. Compare their flow rates, pressure ratings, compatibility, and reliability to shortlist the most suitable options.

- Read customer reviews: Customer reviews can offer valuable insights into the performance and reliability of specific fuel pumps. Pay attention to reviews from customers who own a similar vehicle as yours.

- Seek professional advice: If you’re unsure about which fuel pump to choose, consult a qualified mechanic or automotive expert. They can provide personalized guidance based on your vehicle’s needs.

By following these steps, you can make an informed decision and select the right electric fuel pump that matches your vehicle’s specifications, ensuring optimal performance and longevity.

Preparing For Installation

Before you begin installing an electric fuel pump, it’s important to gather the necessary tools and equipment, locate and access the fuel pump location in your vehicle, and take the necessary safety precautions. This section will guide you through each step, ensuring a smooth installation process.

Gathering the necessary tools and equipment

To get started, make sure you have the following tools and equipment handy:

- A wrench set

- A ratchet set

- A fuel line disconnect tool

- A wire stripper

- Electrical tape

- A multimeter or test light

- A clean cloth

- A drain pan

- A new electric fuel pump

- New fuel pump gaskets or seals

Locating and accessing the fuel pump location in your vehicle

The fuel pump location can vary depending on the make and model of your vehicle. To locate it, refer to your vehicle’s manual or do an online search specific to your vehicle. Once you have located the fuel pump, you will need to access it by following these steps:

- Place the vehicle on a level surface and engage the parking brake to ensure stability.

- Locate the fuel tank and find the access cover or plate that conceals the fuel pump.

- Using the appropriate tools, remove the access cover or plate to reveal the fuel pump and its components.

Safety precautions to take before beginning the installation process

Before starting the installation, it’s crucial to take the necessary safety precautions to ensure your well-being and the integrity of your vehicle. Here are some key steps to observe:

- Make sure the engine is cool before starting the installation process to avoid any risk of burns.

- Wear appropriate protective gear, such as gloves and safety glasses, to protect yourself from any hazardous materials.

- Disconnect the vehicle’s battery to avoid any electrical shock or damage during the installation process.

- Relieve the fuel system’s pressure by locating the fuel pump fuse or relay and removing it. Then, start the vehicle and let it run until it stalls to release any remaining fuel pressure.

- Place a drain pan underneath the fuel pump to catch any fuel that may leak during the installation process.

By gathering the necessary tools and equipment, locating and accessing the fuel pump, and taking the appropriate safety precautions, you’ll be well-prepared to begin the installation process. In the next section, we’ll guide you through the steps involved in installing the electric fuel pump.

Installing The Electric Fuel Pump

Installing an electric fuel pump is a task that many DIYers can tackle with the right tools and a little bit of patience. Whether you’re upgrading to a more powerful pump or replacing a faulty one, this step-by-step guide will walk you through the process. Follow these instructions to ensure a safe and successful installation.

Disconnecting the negative battery cable

The first step in any electrical installation is to disconnect the negative battery cable. This will prevent any accidental sparks or electrical shock while you’re working on the fuel pump. Locate the battery in your vehicle and use a wrench to loosen the nut on the negative terminal. Once the nut is loose, slide the cable off the terminal and set it aside. Keep in mind that some vehicles may require special tools to disconnect the battery cable.

Removing the old fuel pump (if applicable)

If you’re replacing an old fuel pump, you’ll need to start by removing it from your vehicle. The exact steps for removal may vary depending on the make and model of your car, so consult your owner’s manual or a repair guide for specific instructions. In general, you’ll need to locate the fuel pump, disconnect the fuel lines and electrical connections, and then remove any mounting brackets or screws that are holding the pump in place. Once everything is disconnected, carefully lift the old pump out of the fuel tank or off the frame.

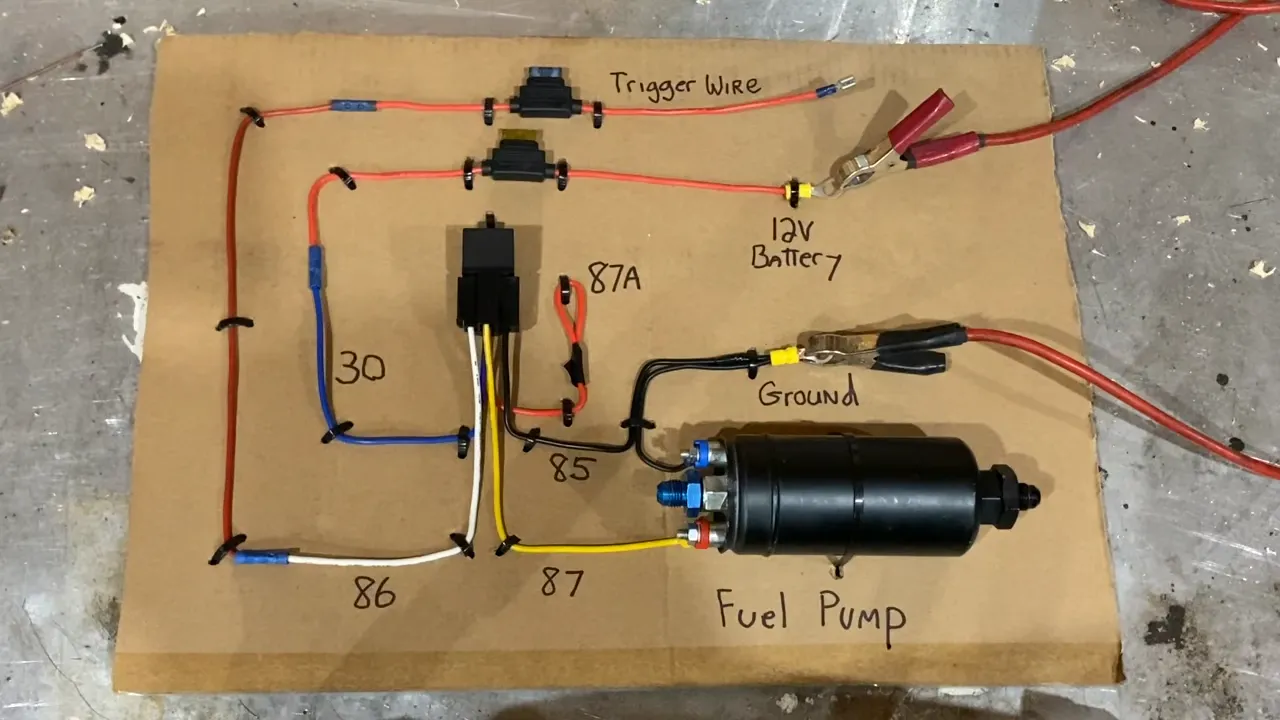

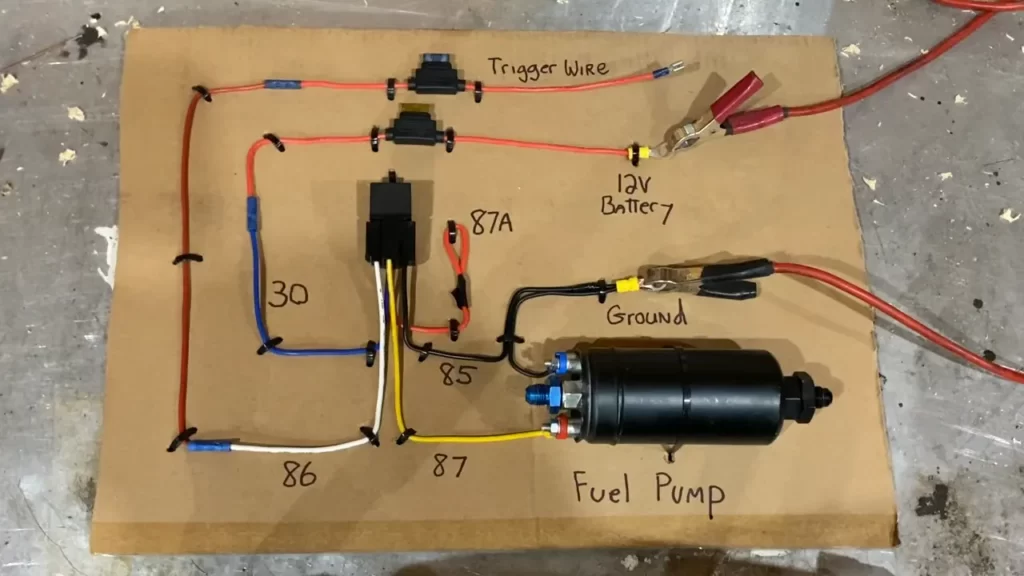

Connecting the new electric fuel pump

Now that the old pump is out, it’s time to connect the new electric fuel pump. Start by positioning the pump in the same location as the old one. If necessary, use mounting brackets or screws to secure the pump to the fuel tank or frame. Once the pump is in place, you’ll need to reconnect the fuel lines and electrical connections. Make sure the lines are properly aligned and push them firmly onto the pump fittings. For the electrical connections, match the wires from the pump with the corresponding wires in your vehicle’s wiring harness and secure them with electrical connectors or wire nuts.

Securing the pump to the fuel tank or frame

After connecting the new pump, it’s important to secure it properly to the fuel tank or frame. This will help prevent any movement or vibration during operation. If your pump came with specific mounting brackets or screws, use them according to the manufacturer’s instructions. Ensure that the pump is tightly secured, but be careful not to overtighten any screws or brackets, as this could damage the pump or fuel tank.

Attaching the fuel lines and electrical connections

With the pump securely in place, you can now attach the fuel lines and electrical connections. Take a moment to double-check that the fuel lines are properly aligned with the pump fittings. Then, firmly push the lines onto the fittings until they click into place. For the electrical connections, make sure all wires are securely connected and insulated. You may want to use electrical tape or zip ties to tidy up any loose wires and prevent them from rubbing against other components.

Testing the newly installed electric fuel pump

Before you finish up, it’s important to test the newly installed electric fuel pump to ensure it’s functioning correctly. Reconnect the negative battery cable by sliding it onto the terminal and tightening the nut with a wrench. Once the battery is reconnected, turn the ignition to the “on” position (without starting the engine) and listen for the sound of the fuel pump running. If you hear a humming noise, it means the pump is working. Additionally, you can check for any fuel leaks around the connections and inspect the fuel pressure gauge (if present) to ensure it’s within the manufacturer’s specifications. If everything looks good, start your engine and verify that the fuel pump continues to operate smoothly.

By following these steps, you’ll be able to confidently install an electric fuel pump in your vehicle. Remember to always consult your owner’s manual or repair guide for any specific instructions or precautions related to your vehicle. If you’re not comfortable performing this installation yourself, it’s always best to seek the help of a professional mechanic. With the proper installation, your new electric fuel pump will provide reliable and efficient fuel delivery, ensuring your vehicle runs smoothly for miles to come.

Troubleshooting And Maintenance

After successfully installing your electric fuel pump, it is important to be aware of the common issues that may arise during or after the installation process. Additionally, regular maintenance plays a crucial role in prolonging the lifespan of your electric fuel pump. In this section, we will discuss the common issues, diagnostic methods, and regular maintenance practices you should follow.

Common issues that may arise during or after installation

Despite following the installation instructions diligently, a few common issues may still occur. Being aware of these issues and their possible causes will help you quickly troubleshoot and resolve them. Here are some common issues that you may encounter:

- No power: If you notice that your electric fuel pump is not receiving power or not functioning at all, the first thing to check is the electrical connections. Ensure that all the wires are securely connected and not damaged.

- Fuel leaks: Another issue that may arise is fuel leakage. It is essential to inspect the fuel lines, connectors, and fittings for any potential leaks that can result in fuel wastage and compromise the performance of your electric fuel pump.

- Excessive noise: If you hear loud noises coming from your electric fuel pump, it may indicate a problem. This could be due to the pump running at a higher speed than usual, loose connections, or a faulty pump. Taking immediate action can prevent further damage.

- Overheating: Overheating is a common problem faced by electric fuel pumps. Insufficient ventilation, high ambient temperatures, or the pump being constantly overloaded can lead to overheating. Regular checks and preventive measures can help mitigate this issue.

Diagnostic methods to identify potential problems

Diagnostic methods are essential in identifying potential problems with your electric fuel pump. By using these methods, you can quickly pinpoint the issue and take appropriate action. Here are some diagnostic methods you can employ:

- Pressure testing: Conducting a pressure test will help you determine if your electric fuel pump is supplying fuel at the correct pressure. This will allow you to identify any pressure-related issues that may arise.

- Flow testing: Testing the flow rate of your electric fuel pump will help ensure that it is delivering the required volume of fuel. A flow test can help identify restrictions in the fuel lines or a faulty fuel pump.

- Checking electrical connections: Regularly inspecting the electrical connections, wires, and contacts is crucial. Loose connections or damaged wires can cause issues with the functioning of your electric fuel pump. Addressing these problems promptly will prevent further damage.

- Listening for abnormal sounds: Paying attention to any unusual sounds, such as grinding or clicking noises, can indicate potential problems with your electric fuel pump. Any abnormal sounds should be investigated further.

- Visual inspection: Regularly examining all components of your electric fuel pump, including fuel lines, connectors, and fittings, can help you identify any physical damage or signs of wear and tear. Addressing these issues early can prevent further complications.

Regular maintenance to prolong the lifespan of the electric fuel pump

Regular maintenance is crucial for ensuring the longevity and optimal performance of your electric fuel pump. By following these maintenance practices, you can minimize the risk of major issues and extend the lifespan of your pump:

- Inspect and clean fuel filters: Regularly inspect and clean the fuel filters to ensure that they are not clogged with debris. Clogged fuel filters can restrict fuel flow and strain the electric fuel pump, leading to decreased performance.

- Check fuel lines for damage: Perform routine checks on the fuel lines to identify any signs of leakage, cracks, or wear. Damaged fuel lines can compromise the fuel delivery and put additional strain on the electric fuel pump.

- Monitor fuel pressure: Keep an eye on the fuel pressure readings, as a sudden decrease or increase can indicate a problem. Regularly monitoring the fuel pressure will allow you to address any issues promptly.

- Ensure proper electrical connections: Regularly inspect and tighten all electrical connections to prevent any loose connections that could result in poor performance or safety hazards.

- Follow manufacturer’s guidelines: Adhere to the maintenance guidelines provided by the manufacturer. These guidelines often include specific recommendations for inspection intervals, replacement of components, and lubrication.

By being proactive in troubleshooting, utilizing diagnostic methods, and following regular maintenance practices, you can ensure the optimal performance and longevity of your electric fuel pump. This will help you avoid costly repairs and enjoy a smoother driving experience. Stay vigilant and take timely action to keep your electric fuel pump in top shape.

Additional Tips And Considerations

Additional Tips and Considerations

When it comes to installing an electric fuel pump, there are a few additional tips and considerations that can greatly contribute to a successful installation. These tips will help you avoid potential challenges and ensure that you have the necessary resources to overcome any obstacles that may arise during the process.

Best practices for a successful installation

Follow these best practices to ensure a successful electric fuel pump installation:

- Prepare the installation area: Before starting the installation, make sure the area is clean and free of debris. This will help prevent any contaminants from entering the fuel system.

- Disconnect the battery: It is essential to disconnect the negative terminal of the vehicle’s battery before proceeding with the installation. This will prevent any accidental sparks or electrical shock.

- Refer to the manufacturer’s instructions: Each electric fuel pump may have specific installation instructions provided by the manufacturer. Make sure to carefully read and follow these instructions to ensure proper installation.

- Use the correct tools: Make sure to use the appropriate tools for the installation, as specified by the manufacturer. This will help prevent damage to the fuel pump or other components.

- Secure the wiring: Properly secure and route the wiring to prevent any interference or damage during operation. Use zip ties or mounting brackets to keep the wiring in place.

- Test the fuel pump: After installation, it is crucial to test the electric fuel pump to ensure proper functionality. Follow the manufacturer’s instructions for testing procedures.

Potential challenges and how to overcome them

During the installation process, you may encounter certain challenges. Here are some common challenges and how to overcome them:

- Compatibility issues: Ensure that the electric fuel pump you have purchased is compatible with your vehicle make, model, and year. Check with the manufacturer or consult a professional if you are uncertain.

- Electrical connection problems: If you are experiencing difficulties with the electrical connections, double-check the wiring diagram provided by the manufacturer. Ensure that all connections are secure and free from any corrosion.

- Fuel system leaks: After installation, inspect the fuel system for any leaks. Use a fuel pressure gauge to check for proper pressure. If leaks are detected, check the connections and seals for any signs of damage or improper installation.

- Fuel pump noise: If your electric fuel pump is making excessive noise, it could indicate a problem. Check for any loose mounting brackets or improper alignment. Confirm that the pump is properly lubricated.

Recommended resources for further assistance or information

For further assistance or more information on installing an electric fuel pump, refer to the following resources:

| Resource | Description |

|---|---|

| mechanicalee.com | A comprehensive guide on electric fuel pump installation with step-by-step instructions and troubleshooting tips. |

| YouTube – Electric Fuel Pump Installation | A video tutorial demonstrating the process of installing an electric fuel pump, providing visual guidance along the way. |

| Auto Forums – Electric Fuel Pump Discussion | An online community where users can post questions and share their experiences related to electric fuel pump installations. |

By following these best practices, being prepared for potential challenges, and utilizing the recommended resources, you will be well-equipped for a successful electric fuel pump installation.

Frequently Asked Questions

Do You Need A Return Fuel Line For A Electric Fuel Pump?

Yes, an electric fuel pump requires a return fuel line. This line allows excess fuel to be returned to the fuel tank, preventing pressure buildup and ensuring proper functioning of the pump. It also helps to maintain a consistent fuel flow and prevents overheating of the pump.

Is It Better For A Electric Fuel Pump To Push Or Pull?

An electric fuel pump is better at pushing fuel rather than pulling it. Pushing helps maintain a consistent flow and pressure, reducing the risk of airlocks and fuel starvation.

Can I Put An Electric Fuel Pump On A Carbureted Engine?

Yes, you can install an electric fuel pump on a carbureted engine. It can provide a consistent fuel supply, enhance performance, and improve reliability. However, ensure proper installation and compatibility with the engine’s fuel system to prevent any negative effects on the engine’s performance.

How To Replace Mechanical Fuel Pump With Electric?

To replace a mechanical fuel pump with an electric one, follow these steps: 1. Disconnect the battery and relieve fuel pressure. 2. Remove the mechanical pump and install the electric pump. 3. Connect the pump to the fuel line and secure it properly.

4. Wire the pump to a power source, such as the ignition switch. 5. Reconnect the battery and test the new electric fuel pump. Ensure proper installation and consult a professional if needed.

Conclusion

Installing an electric fuel pump is a crucial step in optimizing your vehicle’s performance. By following the simple steps outlined in this guide, you can ensure a seamless installation process. Remember to prioritize safety by disconnecting the battery and working in a well-ventilated area.

Regular maintenance and proper installation of your electric fuel pump can improve fuel efficiency and prolong your vehicle’s lifespan. So, take the plunge and enjoy the benefits of a well-functioning electric fuel pump.