To install a toilet flapper, start by turning off the water supply, removing the old flapper, and cleaning the flapper seat. Then, attach the new flapper and adjust the chain length for proper fit.

Installing a toilet flapper is a simple process that can be done in a few steps. It is important to ensure that your toilet flapper is in good working condition to prevent water leaks and maintain the efficiency of your toilet.

In this guide, we will walk you through the steps to install a toilet flapper. By following these instructions, you can easily replace your old flapper with a new one and keep your toilet functioning properly. Let’s dive in and get started.

Factors To Consider When Selecting A Toilet Flapper

Choosing the right toilet flapper is crucial for maintaining the efficient functioning of your toilet. The flapper is responsible for controlling the flow of water from the tank to the bowl, and if it’s not working properly, you could be dealing with leaks, low flushing power, and higher water bills. To help you make an informed decision, here are three key factors to consider when selecting a toilet flapper.

Understanding the Different Types of Toilet Flappers

Before you begin your search for the perfect flapper, it’s important to familiarize yourself with the different types available. Each type has its own unique features and functions, so selecting the right one for your toilet is crucial.

Here are some common types of toilet flappers:

- Rubber flappers: These are the most common type and are typically made of rubber or silicone. They are easy to install and provide a reliable seal.

- Adjustable flappers: These flappers allow you to adjust the amount of water that flows into the bowl, giving you more control over the flushing power.

- Flush valve flappers: Designed specifically for older toilets with flush valves, these flappers have a different shape and size compared to traditional rubber flappers.

Compatibility with Your Toilet Model

When selecting a toilet flapper, it’s important to ensure compatibility with your specific toilet model. Different toilets may require specific flapper sizes, shapes, and attachment mechanisms. Without the right fit, you may experience leaks or suboptimal flushing performance.

To determine the compatibility of a flapper with your toilet, take note of the following:

- Flapper size: Measure the size of your current flapper or consult your toilet’s manufacturer to find out the appropriate flapper size.

- Flapper attachment: Some toilets may have unique attachment mechanisms such as clips or chains. Make sure the flapper you choose is compatible with your toilet’s attachment system.

- Toilet brand and model: Certain toilet brands may have proprietary flapper designs. Check with the manufacturer to find the recommended flapper for your specific model.

Durable Materials for Long-lasting Performance

To ensure long-lasting performance, opt for a toilet flapper made from durable materials. The constant exposure to water and flushing can cause flappers to wear out over time, leading to leaks and water wastage. Choosing a flapper made from sturdy materials can help prevent these issues.

Here are some durable materials commonly used for toilet flappers:

| Material | Advantages |

|---|---|

| Rubber | Flexible and provides a reliable seal |

| Silicone | Durable and resistant to harsh chemicals |

| Chlorazone rubber | Highly resistant to wear, chlorine, and bacteria |

By considering the different types of flappers, ensuring compatibility with your toilet model, and choosing durable materials, you can confidently select a toilet flapper that will provide efficient flushing and minimize water wastage.

Essential Tools For Toilet Flapper Installation

Installing a toilet flapper may seem like a daunting task, but with the right tools, it can be a breeze. Having the essential tools on hand will make the installation process smoother and more efficient. So, let’s take a look at the tools you’ll need:

Adjustable Wrench

An adjustable wrench is a must-have tool for any toilet flapper installation. This versatile tool can be adjusted to fit different sizes of nuts and bolts, making it perfect for loosening and tightening connections.

Screwdriver

A screwdriver is another essential tool you’ll need for toilet flapper installation. It will come in handy for removing screws that hold the toilet tank lid in place, as well as any other screws that need to be loosened or tightened during the process.

Bucket or Towels for Water Cleanup

Water cleanup is an unavoidable part of toilet flapper installation. To prevent any mess and make the cleanup easier, it’s essential to have a bucket or towels on hand. A bucket can be placed directly under the toilet tank to catch any water during the process, while towels can be used to wipe up any spills or leaks.

Safety Gloves

Safety should always be a top priority during any home improvement project. When handling toilet flappers or working with the toilet tank, it’s crucial to protect your hands. Safety gloves will keep your hands safe from any sharp edges or chemicals that may be present.

By having these essential tools ready before starting your toilet flapper installation, you’ll be well-prepared and confident in completing the task. Remember, investing in the right tools will not only make the installation process smoother but also ensure a successful and leak-free result.

Required Materials For Toilet Flapper Installation

Installing a toilet flapper is a relatively simple task that can be done by anyone with a few basic tools. To ensure a smooth installation process, it’s important to gather all the necessary materials beforehand. In this section, we will discuss the three main items you will need for toilet flapper installation: a new toilet flapper, replacement hardware (if necessary), and plumbing grease (optional).

New Toilet Flapper

To replace a malfunctioning or outdated flapper, you will need a new one. It is important to choose a flapper that is compatible with your toilet model. Flappers come in various shapes and sizes, so it’s essential to check your toilet’s brand and model number before purchasing a replacement. Additionally, consider the material of the flapper. Most flappers are made of rubber, which is a durable and flexible material that helps create a proper seal when the toilet is flushed.

Replacement Hardware (if necessary)

While replacing the flapper, you might also need to replace certain hardware components that are essential for its proper functioning. These hardware parts may include the flapper chain, lift arm, or flush valve gasket. Inspect these components while removing the old flapper, and if any of them appear damaged or worn out, it is recommended to replace them to ensure optimal performance. Take note of the size and specifications of the hardware to ensure a proper fit.

Plumbing Grease (optional)

In some cases, using plumbing grease can be beneficial during the toilet flapper installation process. This optional step can help lubricate the moving parts of the flapper system, allowing for smoother and quieter operation. Plumbing grease can also help prevent friction and extend the lifespan of the flapper. Before applying the grease, make sure to read the manufacturer’s instructions and check if it is compatible with the materials used in your toilet’s flapper system.

Step 1: Prepare For Installation

Before you begin the installation process, it is crucial to prepare yourself and the area for the task at hand. Following these simple steps will ensure a smooth experience and successful installation of your new toilet flapper.

Shut Off the Water Supply

The first step in preparing for the installation of a new toilet flapper is to shut off the water supply. Locate the water shut-off valve, usually located near the base of the toilet on the wall or floor. Turn the valve clockwise until it is completely closed. This will prevent any water flow during the installation process, eliminating any potential mess or accidents.

Empty the Toilet Tank

With the water supply turned off, it’s time to empty the toilet tank. Flush the toilet to drain any remaining water in the tank. You can also use a sponge or a bucket to remove any excess water that might be left behind. It’s essential to have a dry and empty tank before you proceed with the installation to ensure a proper seal and fit.

Remove the Old Flapper

Now that the water supply is shut off, and the tank is empty, it’s time to remove the old flapper. Lift the toilet tank lid and locate the flapper, which is typically attached to a chain or hinge. Carefully disconnect the flapper from the chain or hinge and remove it from the overflow tube. Take note of how the old flapper was installed; this will help you during the installation of the new flapper.

Once the old flapper is removed, inspect it for any signs of damage or deterioration. A flapper that is cracked or worn will not create a proper seal, resulting in water leaks and inefficiency. If you notice any issues with the old flapper, it’s time to replace it with a new one.

With Step 1 completed, you’re now ready to move on to the next step in installing your new toilet flapper. It’s essential to follow each step closely to ensure a successful installation and a properly functioning toilet. Stay tuned for Step 2: Installing the New Flapper.

Step 2: Inspect And Clean The Flapper Valve Seat

Once you have successfully removed the old flapper, the next step in installing a new toilet flapper is to inspect and clean the flapper valve seat. This crucial step ensures a proper seal and helps prevent any leaks or inefficiencies in your toilet’s flushing mechanism.

Check for Any Build-up or Debris

Before you move forward with cleaning the valve seat, it’s important to thoroughly check for any build-up or debris that might be affecting its performance. Over time, mineral deposits, grime, and residue can accumulate on the flapper valve seat, compromising its ability to create a tight seal.

To check for any build-up or debris, follow these simple steps:

- Remove the new flapper from its packaging, making sure to keep it separate.

- Take a close look at the valve seat and inspect for any visible signs of dirt, mineral deposits, or corrosion.

- Use a flashlight to get a better view if necessary.

- If you notice any build-up or debris, proceed to the next step to clean the valve seat thoroughly.

Clean the Valve Seat to Ensure a Proper Seal

Keeping the valve seat clean is vital for a proper seal and optimal flushing performance. Here’s how you can clean the flapper valve seat effectively:

- Turn off the water supply to your toilet by shutting off the water valve located behind or underneath the toilet tank.

- Flush the toilet to empty the tank and minimize water in the bowl.

- Locate the flapper valve seat, which is where the flapper sits when the toilet is not in use.

- Using a gentle cleaning solution, such as a mixture of vinegar and water or a mild bathroom cleaner, moisten a soft brush or cloth.

- Scrub the valve seat gently, focusing on removing any build-up, mineral deposits, or residue that may be present.

- Rinse the valve seat thoroughly with clean water to ensure no cleaning agent remains.

- Inspect the valve seat again to make sure it is clean and free from any debris or obstructions.

By thoroughly inspecting and cleaning the flapper valve seat, you’re taking a proactive approach to ensure a proper seal and prevent future issues with your toilet’s flushing mechanism. This simple step goes a long way in maintaining the efficiency and functionality of your toilet.

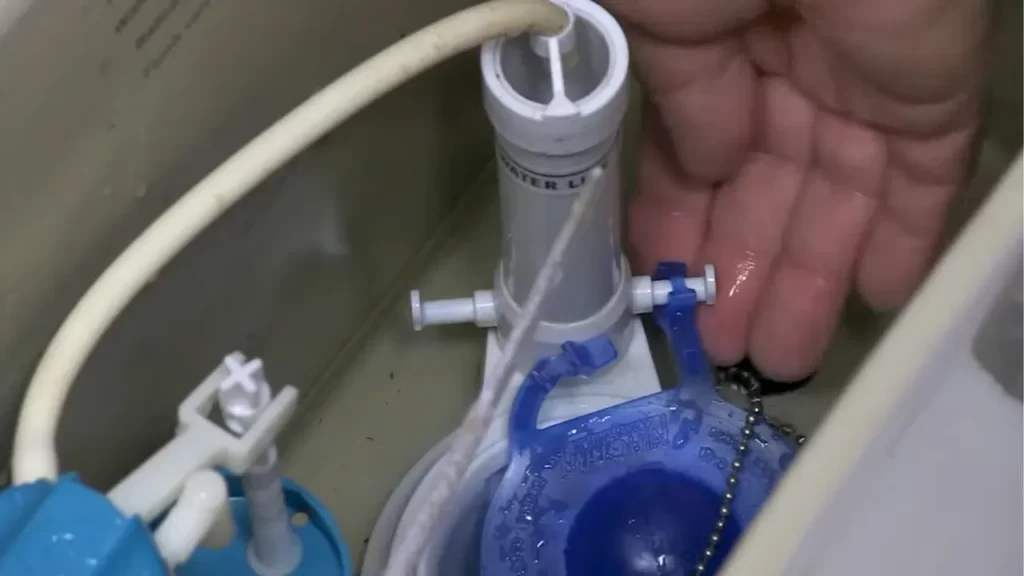

Step 3: Install The New Flapper

Once you have successfully removed the old flapper, it’s time to install the new one. This step is crucial in ensuring the proper functioning of your toilet’s flush mechanism. Follow the steps below to install the new flapper correctly.

Align the Flapper over the Flush Valve Opening

Positioning the flapper correctly is essential for a leak-free flush. Start by aligning the flapper over the flush valve opening. This opening is usually a round hole located at the bottom of the tank. Make sure the flapper is centered directly over the hole to ensure a proper seal. Take extra care to position it correctly to prevent any water leakage in the future.

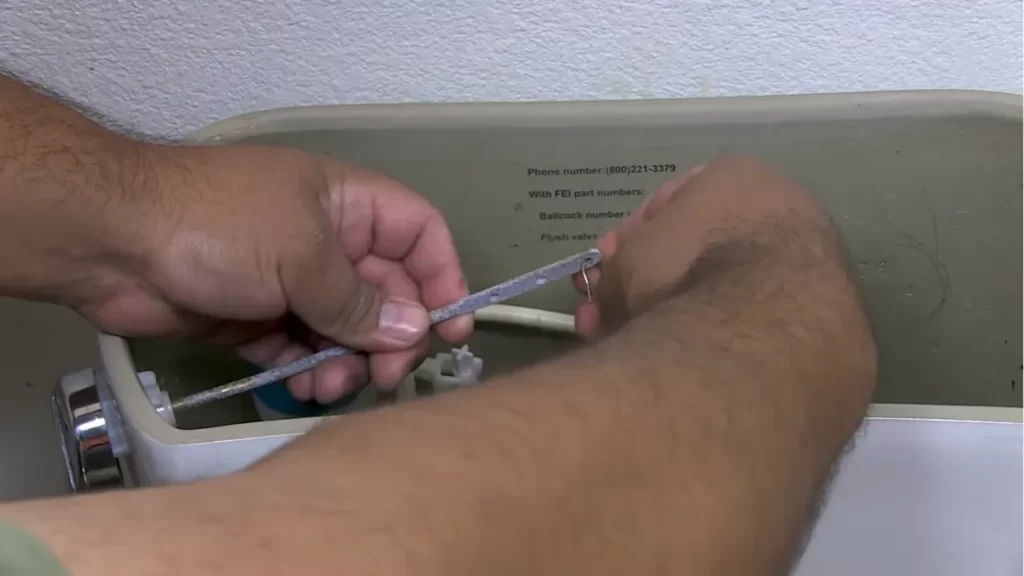

Attach the Flapper Chain to the Flush Lever

The flapper chain plays a vital role in connecting the flapper to the flush lever. Attach one end of the flapper chain to the small hole or hook on the flush lever. The length of the chain should be such that it allows the flapper to move freely when the flush lever is pressed. Adjust the chain length as necessary to ensure smooth operation of the flapper. Avoid excessive slack or tightness in the chain, as it can interfere with the flapper’s movement and lead to improper flushing.

Adjust the Chain Length for Proper Flapper Operation

To achieve optimal flapper operation, it’s essential to adjust the chain length properly. The chain should be long enough to allow the flapper to fully open when the toilet is flushed, but not so long that it gets tangled or caught beneath the flapper. Test the chain length by flushing the toilet and observing the flapper’s movement. If the flapper does not lift high enough or closes too quickly, adjust the chain length accordingly. Remember, proper chain length is crucial for achieving an effective flush and preventing any water wastage or leakage.

With these three simple steps, you can easily install a new toilet flapper and ensure the smooth functioning of your toilet’s flush mechanism. Taking the time to install the flapper correctly will help you save water, prevent leaks, and maintain a fully operational toilet.

Step 4: Test The Flapper

After installing the toilet flapper, it’s crucial to test its performance before calling it a job well done. This step ensures that the flapper functions properly and allows efficient flushing. In this section, we will guide you through the necessary tasks to test the flapper and make any adjustments for optimal operation.

Turn On the Water Supply

Once the flapper is securely installed, it’s time to turn on the water supply. Find the shut-off valve, typically located behind the toilet, and rotate it counterclockwise until fully open. This will allow water to flow into the tank and create the necessary water pressure for proper flushing.

Observe the Flapper’s Performance

With the water supply turned on, closely observe the flapper’s performance during a flush. Pay attention to whether it lifts fully when the handle is pressed and if it falls back into place tightly after the flush is complete. A well-functioning flapper should create a secure seal when closed and allow water to flow smoothly when open.

Make Adjustments for Optimal Operation

If you notice any issues with the flapper’s performance, adjustments may be necessary to ensure optimal operation. Start by examining the chain length connecting the flapper to the toilet handle. It should have a slight slack, allowing the flapper to open fully without any constraints. Adjust the chain as needed to achieve the appropriate length.

If the flapper doesn’t close tightly, resulting in water continuously leaking into the toilet bowl, adjust the chain length to increase tension. This should assist in creating a secure seal and prevent unnecessary water wastage.

Additionally, check the flapper for any signs of wear or damage. A deteriorated flapper can hinder its performance and may require replacement. Ensure the flapper is clean and free from any debris that might impede its functionality.

By testing the flapper’s performance, making necessary adjustments, and ensuring its optimal operation, you can have a well-functioning toilet that efficiently flushes the waste away while minimizing water usage. Remember, a properly working flapper not only contributes to the overall functionality of the toilet but also helps conserve water, which is crucial for a sustainable and eco-friendly household.

Flapper Does Not Seal Properly

A toilet flapper is an essential component of your toilet’s flush system. It is responsible for creating a tight seal that prevents water from constantly running into the toilet bowl. However, there are instances when the flapper does not seal properly, causing water wastage and potential leaks. In this section, we will explore two common reasons for a faulty seal and how to fix them.

Check for Misalignment or Debris on the Flapper or Valve Seat

If your toilet flapper is not sealing properly, the first thing you should do is examine it for any misalignment or debris that may be preventing a tight seal. Over time, minerals and sediment can build up on the flapper and valve seat, hindering their proper function. Follow these steps to check and clean the flapper and valve seat:

- Turn off the water supply to the toilet by closing the shut-off valve located behind the bowl.

- Remove the lid of the toilet tank and locate the flapper and valve seat.

- Inspect the flapper for any visible signs of wear, cracks, or misalignment. If necessary, replace the flapper with a new one.

- Carefully inspect the valve seat for any debris or mineral buildup. If you notice any blockage, gently clean it using a soft cloth soaked in vinegar or a mild toilet bowl cleaner. Avoid using abrasive cleaners or brushes that can damage the surface.

- After cleaning, reposition the flapper properly over the valve seat and ensure it sits flush.

- Turn on the water supply and flush the toilet to see if the flapper now seals properly.

Adjust Chain Length for a Better Seal

An improper chain length can also cause a faulty seal in the toilet flapper. If the chain is too short, it can prevent the flapper from fully closing, leading to constant water flow. On the other hand, if the chain is too long, it can get caught under the flapper, preventing it from sealing tightly. Follow these steps to adjust the chain length:

- Turn off the water supply and remove the toilet tank lid.

- Locate the chain connected to the flapper and the flush handle.

- If the chain is too short, use pliers to disconnect it from the flush handle and move it to a longer hole on the handle.

- If the chain is too long, disconnect it from the flush handle and move it to a shorter hole, ensuring there is enough slack for proper movement.

- Reconnect the chain to the flush handle and turn on the water supply.

- Flush the toilet to check if the chain length adjustment has resolved the sealing issue.

By checking for misalignment or debris on the flapper or valve seat and adjusting the chain length, you can improve the seal of your toilet flapper, saving water and ensuring proper functionality. Regular maintenance and prompt repairs will extend the lifespan of your toilet’s flush system and prevent potential issues down the line.

Flapper Gets Stuck Or Closes Too Quickly

If you’ve noticed that your toilet flapper is getting stuck or closing too quickly, there are a few simple steps you can take to resolve the issue and ensure your toilet is functioning properly.

Check for Chain Obstructions or Excessively Short Chain Length

One common reason why the flapper may get stuck or close too quickly is due to chain obstructions or an excessively short chain length. To check for chain obstructions, start by removing the toilet tank lid. Look for any objects or debris that may be blocking the chain’s movement. If you find any obstructions, remove them and make sure the chain can move freely.

If the chain is too short, it can cause the flapper to close prematurely. Adjust the chain length by loosening the chain’s attachment to the flush lever. Ensure that there is just enough slack in the chain to allow the flapper to close completely but not so much that it becomes tangled or hinders proper flushing.

Lubricate the Flapper Pivot Point with Plumbing Grease

Another reason why the flapper may get stuck or close too quickly is due to lack of lubrication. Over time, the pivot point where the flapper moves can become dry and cause friction, leading to sticking or rapid closure.

To resolve this, apply a small amount of plumbing grease to the pivot point. Plumbing grease is specifically designed to withstand the water and chemicals found in toilets, making it the ideal lubricant for this purpose. Apply a thin layer of grease and ensure it is evenly distributed around the pivot point.

By lubricating the flapper pivot point, you can help the flapper move smoothly and prevent it from sticking or closing too quickly. This simple maintenance step can significantly improve the performance and longevity of your toilet flapper.

Ensuring that your toilet flapper does not get stuck or close too quickly is important for proper flushing and water conservation. By checking for chain obstructions or adjusting the chain length and lubricating the flapper pivot point, you can easily resolve these issues and maintain a well-functioning toilet. Regular maintenance and inspection of your toilet flapper is essential to prevent further problems in the future.

Flapper Does Not Flush Completely

One common issue with toilets is when the flapper does not flush completely. This can be quite frustrating as it can lead to repeated flushing or even clogs. However, there are a few simple steps you can take to resolve this problem. In this article, we’ll discuss how to verify proper chain length and tension, as well as ensuring the flapper valve seat is clean and smooth.

Verify Proper Chain Length and Tension

The chain connected to the flush handle and the flapper is responsible for lifting the flapper when you flush the toilet. If the chain is too long or too short, it can affect the flush efficiency. Here’s how you can ensure the proper chain length and tension:

- Start by removing the toilet tank lid and locating the chain connected to the flush handle.

- Check if the chain has too much slack or if it’s too tight. Ideally, there should be a little bit of slack to allow the flapper to close completely after flushing.

- Adjust the chain length by either adding or removing links. Use pliers or a pair of wire cutters to do this.

- Once you’ve adjusted the chain length, make sure it has the right tension. It should be taut enough to lift the flapper but not so tight that it prevents it from closing properly.

Ensure the Flapper Valve Seat is Clean and Smooth

The flapper valve seat is where the flapper rests when it’s in the closed position. Over time, mineral deposits or debris can accumulate on the valve seat, preventing a proper seal and causing partial flushing. To ensure the flapper valve seat is clean and smooth, follow these steps:

- Turn off the water supply to the toilet by closing the shut-off valve.

- Flush the toilet to remove as much water as possible from the tank.

- Inspect the valve seat for any visible buildup or roughness. If you see any, use a gentle abrasive cleaner and a soft cloth or sponge to clean it.

- Thoroughly rinse the valve seat to remove any cleaner residue.

Once you’ve verified the chain length and tension and ensured the flapper valve seat is clean and smooth, you should see an improvement in the flushing performance of your toilet. If the issue persists, it may be necessary to replace the flapper altogether. Regular maintenance and cleaning can help prevent future problems and keep your toilet working efficiently.

Regular Flapper Inspection And Cleaning

Regularly inspecting and cleaning your toilet flapper is an essential part of toilet maintenance. Over time, flappers can become damaged, worn, or clogged with debris and mineral deposits. This can lead to weak flushes, water leakage, and higher water bills. To avoid these issues, it is important to check your toilet flapper for damage or wear, remove any debris or mineral deposits, and replace the flapper if necessary.

Check for Damage or Wear

Check your toilet flapper for any signs of damage or wear. Over time, the rubber material of the flapper can deteriorate due to regular use and exposure to water and cleaning chemicals. Look for cracks, tears, or signs of brittleness in the rubber. Additionally, check the chain attached to the flapper to ensure it is intact and not overly stretched. If you notice any damage or wear, it is a good indication that the flapper needs to be replaced.

Remove Debris or Mineral Deposits

Debris and mineral deposits can accumulate on the flapper and prevent it from forming a tight seal when the toilet is flushed. To remove these deposits, turn off the water supply to the toilet and flush to drain the tank. Carefully lift the flapper to access the edge and underside. Use a soft brush or cloth and mild soap to gently scrub away any debris or deposits. Avoid using abrasive cleaners or scrub brushes, as they can cause further damage to the flapper.

Replace Flapper if Necessary

If your toilet flapper shows significant damage or wear, or if cleaning doesn’t improve its performance, it is time to replace it. Start by turning off the water supply to the toilet and flushing to empty the tank. Remove the old flapper by disconnecting the chain and unhooking it from the flush valve. Take note of the specific type and size of your existing flapper, as there are different models available in the market. Install the new flapper by following the manufacturer’s instructions. Ensure that the chain is properly connected and has some slack but is not overly loose. Turn the water supply back on and conduct a test flush to ensure the flapper is working effectively.

Regularly inspecting and cleaning your toilet flapper will help maintain its functionality and efficiency. By checking for damage, removing debris or mineral deposits, and replacing the flapper when necessary, you can ensure optimal flush performance and water conservation. Incorporating this simple maintenance task into your routine will not only extend the lifespan of your flapper but also prevent potential water-related issues in the future.

Preventative Measures For Flapper Longevity

When it comes to maintaining your toilet’s functionality, it’s essential to take preventative measures to ensure the longevity of its parts. The toilet flapper is a small but crucial component that helps regulate the flow of water from the tank to the bowl. By following these simple steps, you can keep your flapper in excellent working condition for years to come.

Avoid Using Harsh Chemicals in the Toilet Tank

The products we use to clean our toilets can have a significant impact on the lifespan of the flapper. Harsh chemicals, such as bleach or chlorine tablets, may deteriorate the rubber material of the flapper over time. To avoid this, opt for more gentle cleaning solutions that won’t harm the flapper or other components in the tank.

- Instead of using bleach, consider using vinegar or baking soda, which are natural cleaning agents that won’t harm the flapper.

- Alternatively, you can look for eco-friendly toilet bowl cleaners that are specifically formulated to be safe for all toilet components.

Check for Water Leaks and Fix Promptly

Water leaks can be detrimental to the function of the toilet flapper, and if left unchecked, they can cause significant damage to your bathroom and increase water bills. Regularly inspecting your toilet for leaks and promptly fixing them can help extend the life of the flapper.

If you notice water pooling around the base of the toilet or hear continuous running water, it’s likely you have a leak. Follow these steps to address the issue:

- Check the flapper for any signs of damage or wear and tear.

- If the flapper appears worn out, it’s time to replace it with a new one. Flappers are relatively inexpensive and widely available at hardware or plumbing stores.

- Ensure proper installation of the new flapper by following the manufacturer’s instructions.

- If the leak persists after replacing the flapper, consider contacting a professional plumber to diagnose and fix the issue.

Perform Routine Toilet Tank Maintenance

In addition to avoiding harsh chemicals and checking for leaks, performing routine toilet tank maintenance is essential for the well-being of your flapper. Taking a few minutes to inspect and clean the tank periodically can help prevent blockages, mineral buildup, and other issues that can negatively affect the flapper’s performance.

Here are some tips for maintaining your toilet tank:

- Regularly clean the tank by removing any sediment or debris that may have accumulated.

- Inspect the flush valve and flapper for any signs of wear and tear.

- If you notice any mineral buildup, use a soft brush or sponge to gently scrub it away.

By incorporating these preventative measures into your toilet maintenance routine, you can prolong the life of your flapper and ensure that your toilet operates efficiently for years to come.

Frequently Asked Questions

Are Toilet Flappers Easy To Replace?

Toilet flappers are easy to replace. They can be easily removed and replaced with a new one. You don’t need any special tools or plumbing skills for this task. Simply follow the instructions provided with the new flapper and you’ll have a functioning toilet in no time.

How Do You Install A Float Flapper?

To install a float flapper, follow these steps: 1. Turn off the water supply to the toilet. 2. Remove the tank lid and locate the flapper. 3. Disconnect the chain or strap that attaches the flapper. 4. Install the new flapper, ensuring it properly fits over the flush valve.

5. Reattach the chain or strap, and turn on the water supply.

How Do I Stop My Toilet Flapper From Leaking?

To stop a toilet flapper from leaking, follow these steps: 1. Turn off the water supply valve behind the toilet. 2. Flush the toilet to drain the tank. 3. Remove the flapper from the flush valve. 4. Inspect the flapper for any damage or buildup.

5. If necessary, replace the flapper with a new one. 6. Reinstall the flapper and turn the water supply valve back on. 7. Test the toilet to ensure the leak has been fixed.

Do All Flappers Fit All Toilets?

No, not all flappers fit all toilets. Flappers come in different sizes and shapes, so it’s important to find the right one that matches your toilet’s specific requirements. Make sure to check the dimensions and compatibility before purchasing a new flapper.

Conclusion

To conclude, installing a toilet flapper is a simple task that can save you from potential water leaks and wastage. By following the step-by-step guide provided in this blog post, you can successfully replace or install a new flapper in your toilet.

Remember to turn off the water supply, detach the old flapper, attach the new one securely, and test for any leaks. This maintenance task will ensure efficient flushing and prolong the lifespan of your toilet. Start today and enjoy a leak-free bathroom experience.