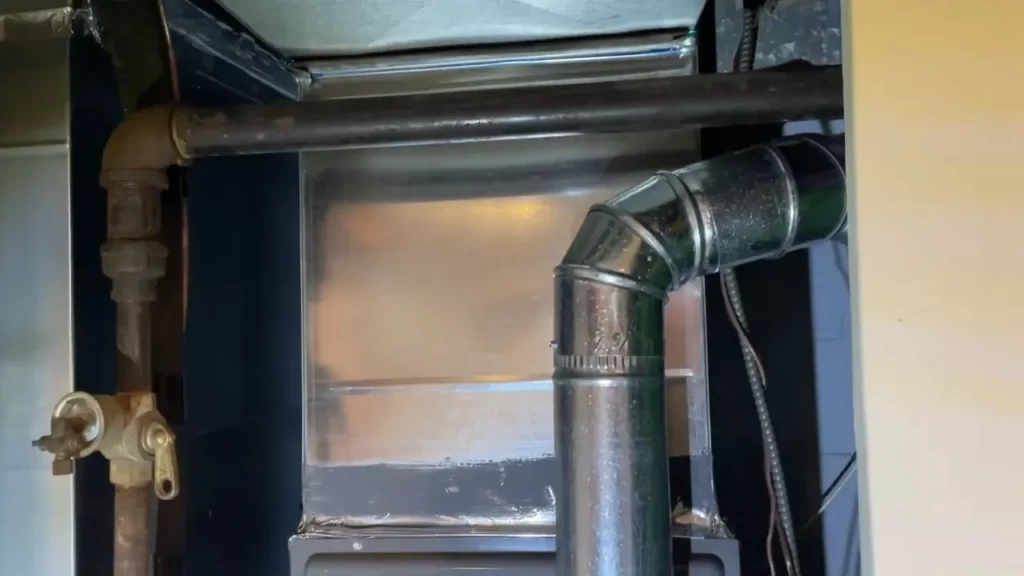

To install a condensate drain line, locate the drain pan outlet on the air conditioner unit and attach a plastic or PVC pipe to it using a coupling or elbow joint. Then, run the pipe downward and secure it to a wall or floor using clamps or brackets, making sure it has a slight slope towards the outside to prevent water from pooling.

Importance Of A Correctly Installed Condensate Drain Line

A condensate drain line is a crucial component of any HVAC (heating, ventilation, and air conditioning) system. Its primary function is to remove the excess moisture generated during the cooling process. However, many homeowners underestimate the importance of a correctly installed condensate drain line, which can lead to a number of issues. In this article, we will explore the reasons why a properly installed drain line is vital for your HVAC system’s performance and your home’s safety.

Avoid potential water damage and costly repairs

One of the main reasons why a correctly installed condensate drain line is essential is to avoid potential water damage and costly repairs. If the drain line is not properly installed, it may become clogged or disconnected, causing water to leak into your home. Excessive water can damage your floors, walls, and furniture, leading to expensive repairs and restoration work. By ensuring that your condensate drain line is correctly installed, you can prevent these issues and save yourself from the headaches and expenses of water damage.

Maintain optimal performance of HVAC systems

A properly installed condensate drain line plays a vital role in maintaining the optimal performance of your HVAC system. When the drain line is correctly installed, it effectively removes the excess moisture that collects in your air conditioning unit. This prevents the accumulation of water in the system, which can lead to reduced efficiency and potential breakdowns. By ensuring that your drain line is installed correctly, you can help your HVAC system operate at its best, providing you with consistent and efficient cooling throughout your home.

Prevent the growth of mold and mildew

In addition to water damage and efficiency issues, a correctly installed condensate drain line also helps prevent the growth of mold and mildew. Excessive moisture can create the perfect environment for these harmful substances to thrive. If your drain line is not properly installed, it may not effectively remove the moisture, leading to the accumulation of water in your air conditioning system. As a result, mold and mildew may start to grow, posing a risk to your health and causing unpleasant odors in your home. By ensuring that your drain line is correctly installed, you can prevent the growth of mold and mildew, keeping your home safe and free from potential health hazards.

In conclusion, a correctly installed condensate drain line is crucial for the overall performance and safety of your HVAC system and home. It helps avoid water damage and costly repairs, maintains optimal performance, and prevents the growth of mold and mildew. By prioritizing the proper installation of your drain line, you can enjoy the benefits of a well-functioning HVAC system while safeguarding your home and health.

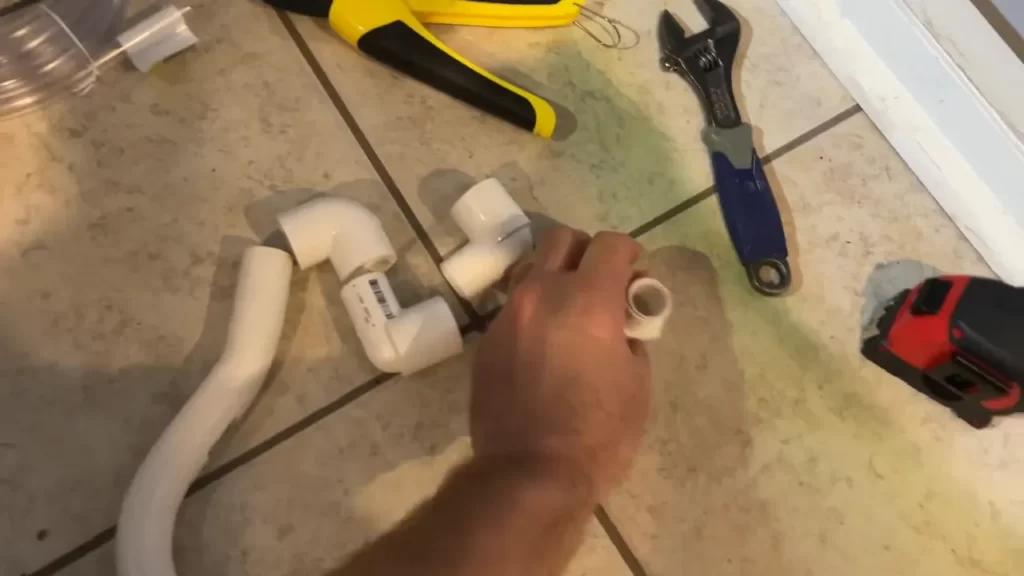

Gathering The Necessary Tools And Materials

When it comes to installing a condensate drain line, gathering the necessary tools and materials beforehand will make the process much smoother. Having the right tools at hand will ensure that you can complete the installation without any unnecessary delays or frustrations. Likewise, using recommended materials is essential to ensure the durability and effectiveness of the drain line. In this section, we will discuss the list of tools required for the installation as well as the recommended materials you will need.

List of tools required for the installation

Before you begin installing the condensate drain line, make sure you have the following tools:

| Tool | Description |

|---|---|

| Adjustable wrench | A wrench with a movable jaw, used for tightening and loosening nuts and bolts. |

| Hacksaw | A handheld saw with a fine-toothed blade, ideal for cutting plastic or metal pipes. |

| Tubing cutter | A specialized tool used to cut copper or plastic tubing cleanly and accurately. |

| Drill | An electric or battery-powered tool used for drilling holes. |

| Screwdriver set | A set of various screwdrivers with different sizes and types of tips. |

| Teflon tape | A thin, white tape used to create a watertight seal on threaded connections. |

Recommended materials for the drain line

When it comes to choosing the materials for your condensate drain line, it’s important to use those that are suitable for its intended purpose. Here are the recommended materials:

- PVC pipe: Sturdy and resistant to corrosion, PVC pipe is commonly used for condensate drain lines. It is available in various sizes and is relatively easy to work with.

- PVC fittings: These fittings, such as elbows, tees, and couplings, are necessary to connect the PVC pipe and create the desired shape and direction for the drain line.

- PVC solvent cement: This adhesive is used to create strong and permanent bonds between PVC components, ensuring leak-free connections.

- PVC cleaner: Before applying the solvent cement, it is important to clean the PVC surfaces using a specialized cleaner to remove any dirt, oil, or debris that could hinder the bonding process.

- Condensate pump: If your HVAC system requires a pump to remove condensate, make sure to choose a reliable and efficient pump that meets the system’s specifications.

By gathering the necessary tools and materials before starting the installation, you’ll be well-prepared to complete the condensate drain line installation with ease. Remember to check the specific requirements of your HVAC system and consult the manufacturer’s instructions for any additional tools or materials that may be needed.

Assessing The Ideal Location For The Drain Line

When it comes to installing a condensate drain line, one of the most crucial steps is determining the ideal location for it. The drain line is responsible for removing the condensation that builds up in your HVAC system, preventing any damage that it might cause. Choosing the right location ensures that the drain line functions effectively and efficiently. In this section, we will discuss the factors to consider when choosing the location of your condensate drain line, as well as how to determine the slope and accessibility.

Factors to Consider When Choosing the Location

When assessing the ideal location for your condensate drain line, there are a few key factors to keep in mind. These factors will not only affect the effectiveness of the drain line but also its longevity, ease of maintenance, and the overall efficiency of your HVAC system. Let’s take a closer look at these factors:

- Proximity to the HVAC equipment: It is important to choose a location that is close to the HVAC equipment, as this will ensure a more efficient drainage system. A shorter distance between the drain line and the equipment reduces the chances of condensation buildup, clogs, and leaks.

- Accessibility for maintenance: The drain line should be easily accessible to allow for regular maintenance and cleaning. Choose a location that provides ample space for inspection and servicing to avoid any potential blockages or malfunctioning.

- Drainage location: Consider the location where you want the condensate to be drained. You may want to direct the drain line towards a suitable drainage system, such as a floor drain or an external pipe. Ensure that the chosen location allows for proper drainage without causing any water damage to the surroundings.

Important Note: It is essential to consult local building codes and regulations for specific requirements regarding the discharge of condensate water. Different regions may have different regulations in place, so it is crucial to adhere to these guidelines. Determining the Slope and Accessibility

Once you have chosen the location for your condensate drain line, you need to determine the proper slope and accessibility for optimal functionality. Here are some steps to follow:

- Slope: The drain line should be installed with a slight downward slope to allow water to flow freely. This prevents any standing water or stagnant condensate which could potentially lead to clogs or water damage. Aim for a slope of at least 1/8 inch for every 1 foot of the drain line.

- Accessibility: Ensure that the drain line is easily accessible for future maintenance and repairs. Avoid installing the drain line in hard-to-reach areas or behind walls where it will be challenging to address any issues that may arise.

- Support: Install supports along the drain line to prevent sagging and ensure proper alignment. This will help maintain the desired slope and prevent any potential blockages.

Summary

Choosing the ideal location for your condensate drain line is crucial for the efficient operation of your HVAC system. Consider factors such as proximity to the HVAC equipment, accessibility for maintenance, and the drainage location. Additionally, determining the proper slope and ensuring accessibility during installation will prevent future issues and prolong the lifespan of your drain line. Follow these guidelines to install a condensate drain line that functions effectively and helps maintain the overall efficiency of your HVAC system.

Shutting Off The Hvac System

Safety Precautions to Take Before Starting the Installation

Before you begin the installation of a condensate drain line, it’s imperative to prioritize safety. Taking the necessary precautions will ensure a smooth and accident-free installation process. Here are some important safety measures to consider:

- Shutting off the power: Before starting any work with the HVAC system, remember to turn off the power supply. Locate the main electrical breaker panel and switch off the circuit breaker dedicated to the HVAC unit. This step will prevent any accidental electrical shocks during the installation.

- Wearing protective gear: Donning the appropriate protective gear is crucial for your safety. Make sure to wear safety glasses to shield your eyes from any debris or fluid splashes. Additionally, wearing gloves will protect your hands from potential cuts or contact with harmful substances.

- Checking for gas leaks: If your HVAC system runs on natural gas, it’s essential to check for gas leaks before proceeding. Use a gas leak detector or soapy water solution to identify any leakage. If you detect a gas leak, immediately stop the installation and contact a professional.

- Working in a well-ventilated area: Proper ventilation is key to ensuring a safe working environment. Open windows or doors to allow fresh air to circulate, especially if you’re working in a confined space.

- Keeping a fire extinguisher nearby: In case of any unexpected fires, having a fire extinguisher nearby is essential. Familiarize yourself with its proper usage and keep it readily accessible throughout the installation process.

Remember, taking safety precautions should be your utmost priority before starting the installation of a condensate drain line. By following these guidelines, you can minimize potential risks and complete the installation with confidence.

Next, let’s move on to the first step of the installation process: shutting off the HVAC system.

Measuring And Cutting The Drain Line

Measuring and cutting the drain line is a crucial step in the installation process of a condensate drain line. It’s important to select the appropriate size for the drain line as well as use the proper cutting technique to ensure a tight and secure fit. In this section, we will go over the steps to follow for each of these tasks, making the installation process more efficient and effective.

Selecting the Appropriate Size for the Drain Line

Before starting the installation, it’s important to determine the appropriate size for the drain line. The size of the drain line will depend on the capacity of your air conditioning system. Using an undersized drain line can lead to issues such as clogs and leaks, while an oversized drain line may not provide enough condensation flow. Refer to the manufacturer’s guidelines or consult a professional to determine the right size for your specific system.

Proper Technique for Cutting the Drain Line

Once you have determined the appropriate size for the drain line, it’s time to cut it to the required length. Follow these steps to ensure a clean and accurate cut:

- Measure Twice, Cut Once: Measure the distance between the condensate drain outlet and the drain point. This will give you the length of the drain line you need. Double-check your measurements to avoid any mistakes.

- Mark the Cut: Using a marker or a pencil, mark the measured length on the drain line. This will serve as a guide for your cutting process.

- Cut Carefully: Using a pipe cutter or a hacksaw, carefully cut the drain line along the marked line. Make sure to keep the cut as straight as possible for a secure fit. If using a pipe cutter, apply consistent pressure while rotating it around the drain line until the cut is complete. If using a hacksaw, use slow and steady strokes to ensure a clean cut.

- Deburring the Cut: After cutting the drain line, use a deburring tool or sandpaper to remove any rough edges or burrs. This step will prevent any obstruction in the flow of condensation.

- Test the Fit: Before proceeding with the installation, test the fit of the cut drain line. Ensure that it fits securely and tightly onto the condensate drain outlet and the drain point. Make any adjustments if necessary.

By following the proper technique for measuring and cutting the drain line, you will ensure a precise and secure fit. This will contribute to the overall efficiency and performance of your condensate drain line installation.

Connecting The Drain Line To The Condensate Pan

Ensuring a Secure Connection

When it comes to connecting the drain line to the condensate pan, it is crucial to ensure a secure connection. A secure connection will prevent any potential leaks or water damage in the future, keeping your HVAC system running smoothly. Here are some steps to follow to ensure a secure connection:

- First, inspect the condensate pan and drain line for any damage or clogs. Make sure they are clean and in good condition.

- Measure the diameter of the condensate drain outlet to select the right size of fittings and adapters. Using the wrong size can result in a loose connection or blockage.

- Choose high-quality fittings and adapters that are compatible with your condensate pan and drain line. This will ensure a tight and secure fit.

- Cut the drain line to the appropriate length, allowing for a slight downward slope towards the condensate pan. This will help to facilitate proper drainage.

- Apply a small amount of plumber’s tape or sealant to the threads of the fittings and adapters. This will help to create a watertight seal.

- Insert the fittings and adapters into the condensate drain outlet and the end of the drain line, ensuring they are fully inserted.

- Tighten the fittings and adapters with a wrench or pliers, being careful not to overtighten and damage the connections.

- Once the drain line is securely connected, test the system by pouring a small amount of water into the condensate pan. Observe if there are any leaks or overflow.

By following these steps and ensuring a secure connection, you can rest assured that your condensate drain line is properly installed. This will help to prevent any potential water damage and keep your HVAC system functioning at its best.

Positioning The Drain Line

Proper positioning of the condensate drain line is crucial for ensuring efficient drainage and preventing potential leaks. When installing the drain line for your condensate system, there are a few key factors to consider to promote optimal performance and avoid any potential issues.

Proper placement of the drain line to promote efficient drainage

When it comes to positioning the drain line, it is essential to consider the direction of condensate flow and gravity. The drain line should be sloped downward at a gradual angle to ensure that water can flow smoothly and efficiently towards the designated drain point.

Make sure to measure the distance between the air conditioning unit or heat pump and the drainage point. This will help determine the length of the drain line required for proper installation. It is crucial to use a flexible PVC drain line that is long enough to reach the drain point without any kinks or bends that could potentially impede water flow.

Avoiding obstacles and potential leaks

When positioning the drain line, it is important to avoid any obstacles that could hinder drainage or cause potential leaks. Ensure that the drain line is routed in a clear path without any sharp bends, obstructions, or tight spaces.

Take note of any electrical wires, gas pipes, or structural components in the vicinity of the installation area. These should be avoided to prevent any accidental damage during the installation process.

Additionally, pay attention to the proximity of the drain line to any potential water sources or vulnerable areas of your property. Position the drain line away from windows, doors, or other areas prone to leaks or water damage to mitigate any potential risks.

| Tip: | Consider using insulated drain line sleeves in areas where the drain line passes through unconditioned spaces, such as attics or crawl spaces. This helps prevent condensation buildup and potential damage to surrounding materials. |

|---|---|

| Tip: | When positioning the drain line, ensure that it is accessible for necessary maintenance and cleaning. This will make it easier to clear any potential clogs or obstructions that may occur over time. |

By properly positioning the drain line and avoiding obstacles or potential leaks, you can ensure efficient drainage for your condensate system. This will help prolong the lifespan of your unit and prevent any unnecessary water damage.

Creating A Trap And Vent

Creating a Trap and Vent

When it comes to installing a condensate drain line, creating a trap and vent is a crucial step. A trap and vent system helps to prevent airlock and ensure the proper functioning of the drain line. In this section, we will discuss the importance of a trap and vent in the drain line and the steps to properly install one.

Importance of a Trap and Vent in the Drain Line

A trap plays a significant role in a condensate drain line as it prevents the entry of air into the drain line. It acts as a barrier, allowing water to pass through while blocking any air that may be present. Without a trap, the drain line can become airlocked, leading to drainage issues and potential damage to the HVAC system.

A vent, on the other hand, ensures the smooth flow of water by allowing air to enter the drain line. It prevents the creation of negative pressure, which can hinder the flow of water and lead to clogging. By providing a vent, you ensure that the drain line operates efficiently and effectively.

Steps to Properly Install a Trap and Vent

Now that we understand the importance of a trap and vent in the drain line, let’s take a look at the steps to properly install one:

- First, locate the best position to create a trap and vent in the drain line. This is usually at the lowest point of the line, where water naturally accumulates.

- Using a pipe cutter, carefully cut the condensate drain line at the chosen location. Ensure that the cut is clean and straight to facilitate proper connection.

- Attach a trap to the cut section of the drain line. Make sure the trap is correctly aligned and securely connected using appropriate fittings.

- Connect the vent pipe to the trap. This pipe will serve as the outlet for the air, allowing it to enter the drain line.

- Secure all connections using clamps or fittings to ensure a leak-free installation.

- Test the trap and vent system by pouring water into the drain line. Observe if the water flows smoothly and without any blockages. If any issues are detected, double-check the connections and make necessary adjustments.

- Once the trap and vent are successfully installed and tested, insulate the drain line if necessary to prevent condensation and potential moisture damage.

By following these steps, you can ensure that your condensate drain line has a properly installed trap and vent system. This will help maintain the proper functioning of the drain line, prevent airlock, and ensure efficient drainage of condensate water from your HVAC system.

Securing The Drain Line And Insulating If Needed

When it comes to installing a condensate drain line, securing it properly is crucial to prevent any potential leaks or movement in the future. In this step, we will outline how to prevent movement and potential leaks and discuss the importance of insulating the drain line for energy efficiency.

Preventing movement and potential leaks

Securing the condensate drain line is essential to ensure it remains in place and does not shift or develop any leaks over time. To prevent movement and potential leaks:

- Use mounting brackets or clips to secure the drain line to the wall or ceiling. Make sure the brackets are spaced evenly along the length of the line to provide sufficient support.

- Check for any loose connections or fittings along the drain line. Tighten them if necessary to prevent leaks.

- Inspect the drain line for any visible damage or holes. If you spot any, replace the affected section immediately to avoid future leaks.

- Consider using a slope on the drain line to ensure proper drainage. The slope should be away from the condensate drain point to prevent any standing water or blockages.

Insulating the drain line for energy efficiency

In addition to securing the drain line, insulating it can provide several benefits, including improved energy efficiency and prevention of condensation buildup. Here’s how you can insulate the drain line:

- Measure the length of the drain line that needs insulation.

- Choose a suitable insulation material that is specifically designed for condensate drain lines. Common options include foam insulation sleeves or wrap.

- Cut the insulation material to the appropriate length and wrap it around the drain line, ensuring full coverage.

- Secure the insulation in place using zip ties or adhesive tape to prevent it from sliding or coming loose over time.

- Pay special attention to areas where the drain line passes through unconditioned spaces, such as the attic or crawl space. Insulating these sections will help minimize heat loss and prevent condensation in colder weather conditions.

By properly securing and insulating the condensate drain line, you can ensure its longevity, prevent potential leaks, and improve energy efficiency in your HVAC system. Take the time to follow these steps, and you’ll enjoy a well-functioning condensate drain system for years to come.

Testing The Newly Installed Drain Line

Once you have successfully installed a condensate drain line, it’s crucial to test its functionality to ensure proper drainage and prevent any leaks. Testing the drain line is an essential step in the installation process, and it will give you confidence that your system is working efficiently. In this section, we will discuss how to check for proper drainage and any leaks that may arise.

Checking for proper drainage

After completing the installation of your condensate drain line, it’s important to verify that the water is flowing in the intended direction and draining as it should. To do this, follow these simple steps:

- Start by pouring a small amount (about a cup) of water into the drain pan or condensate pump.

- Observe the water as it enters the drain line and ensure that it is flowing smoothly without any obstructions or backups.

- Keep an eye on the drain line outlet, typically located outside your home, and confirm that water is being discharged properly.

If you notice any issues during this process, such as water backing up or slow drainage, it may indicate a clog or incorrect installation. Addressing these issues promptly is crucial to prevent damage to your HVAC system.

Making necessary adjustments if needed

If you encounter any problems while testing your newly installed drain line, it’s important to make adjustments to ensure its proper functioning. Here are some steps you can take to remedy any issues:

- Inspect the drain line for any visible clogs or blockages. Clearing any debris or obstructions will allow for free-flowing drainage.

- Check the slope of the drain line to ensure it is at a proper angle. A slight downhill slope helps the water flow smoothly towards the drain outlet.

- Examine the connections between the drain line components, such as the condensate pump or drain pan, and ensure they are tight and secure. Loose connections can cause leaks or inefficient drainage.

By making the necessary adjustments to your newly installed drain line, you can ensure that it functions optimally, preventing any potential issues in the future.

Testing and inspecting your newly installed condensate drain line is a crucial step to guarantee its efficiency and prevent leaks or drainage problems. By following these steps, you can confidently ensure that your HVAC system is working effectively, providing you with comfort and peace of mind.

Regular Maintenance And Troubleshooting Tips

Recommended maintenance schedule for the drain line

Regular maintenance is essential to keep your condensate drain line in good working condition. By following a recommended maintenance schedule, you can prevent clogs and potential water damage. Here are some key steps to include in your maintenance routine:

- Clean the drain line: Start by cleaning the drain line at least once every three months. This will help to remove any debris or buildup that may be blocking the flow of condensate water. You can do this by using a mixture of water and bleach or a specially formulated condensate line cleaner. Simply pour the solution into the drain line and let it sit for a few minutes before flushing it out with water.

- Inspect the drain line for leaks: While cleaning the drain line, it’s also important to inspect it for any leaks. Look for signs of water dripping or pooling near the drain line connection. If you notice any leaks, they should be repaired as soon as possible to prevent further damage.

- Check the drain line slope: The drain line should be installed with a slight slope to ensure proper drainage. Over time, the slope may become uneven or compromised due to settling or other factors. Regularly check the slope of the drain line and make adjustments if necessary to maintain optimal drainage.

- Clear the condensate line trap: The condensate line trap is designed to catch debris and prevent it from entering the drain line. It’s important to regularly check and clean the trap to ensure it is not clogged. Simply remove the trap, clean it with water, and reattach it to the drain line.

- Test the condensate pump (if applicable): If your HVAC system is equipped with a condensate pump, it’s important to test it regularly. Ensure that the pump is functioning correctly and that the water is being pumped out effectively. If you notice any issues with the pump, it may need to be repaired or replaced.

Common issues and how to troubleshoot them

Despite regular maintenance, issues with the condensate drain line may still arise. Here are some common problems you may encounter and how to troubleshoot them:

| Issue | Troubleshooting |

|---|---|

| Clogs | If you notice that the drain line is clogged and water is not properly draining, try using a wet/dry vacuum to remove the blockage. Place the vacuum hose over the end of the drain line and create a seal. Turn on the vacuum to suction out the clog. If this method doesn’t work, you may need to call a professional for further assistance. |

| Leaks | If you discover any leaks in the drain line, check the connections and tighten them if necessary. If the leak persists, replace the damaged section of the drain line or seek professional help. |

| Malfunctioning condensate pump | If the condensate pump is not working correctly, check the power supply and ensure it is securely connected. If the pump is powered but still not functioning, it may need to be repaired or replaced by a qualified technician. |

By following a regular maintenance schedule and troubleshooting common issues, you can ensure your condensate drain line operates efficiently, preventing potential water damage and extending the lifespan of your HVAC system.

Frequently Asked Questions

How Much Does It Cost To Install A Condensate Drain Line?

The cost of installing a condensate drain line can vary depending on factors such as the length of the line and the complexity of the installation. On average, you can expect to pay around $150 to $300 for this service.

It is always recommended to get multiple quotes from qualified professionals to get an accurate estimate.

Where Should I Run My Condensate Drain Line?

The condensate drain line should be installed in a downward slope away from the unit and near a drain or suitable outlet. It should not be placed where it can freeze or cause damage to nearby structures.

What Is The Slope For A Condensate Drain Pipe?

The slope for a condensate drain pipe should be at least 1/4 inch per foot.

What Material Should Be Used For A Condensate Drain Line?

The condensate drain line should be made of corrosion-resistant materials, such as PVC (polyvinyl chloride) or CPVC (chlorinated polyvinyl chloride). These materials are durable and suitable for carrying condensed water from the air conditioning unit or HVAC system.

Conclusion

Learning how to install a condensate drain line is crucial to maintain the efficiency and longevity of your HVAC system. By following the steps outlined in this guide, you can ensure proper drainage and prevent potential water damage. Remember to consult the manufacturer’s instructions and local building codes for additional guidance.

With a little knowledge and some basic tools, you’ll be able to tackle this DIY project with confidence. Keep your HVAC system running smoothly and enjoy a comfortable and safe indoor environment.